Boiler Tube Failure Analysis

Boiler tubes are critical components in petrochemical facilities and power plants, where uninterrupted operation and efficiency are vital. However, tubes often operate under extreme temperature, pressure, and corrosive environments that make them susceptible to a range of damage mechanisms. Failures can lead to costly downtime, safety hazards, and reduced plant reliability. A comprehensive boiler tube failure analysis service is essential to identify root causes, prevent recurrence, and the extend the life of boiler assets. Our team combines water chemistry, metallurgical expertise, advanced laboratory testing, and field experience in chemical industries and power generation environments. We deliver practical, data-driven solutions tailored to plant conditions, ensuring safe, reliable, and cost-effective boiler operation.

Common Failure Mechanisms of Boiler Tubes:

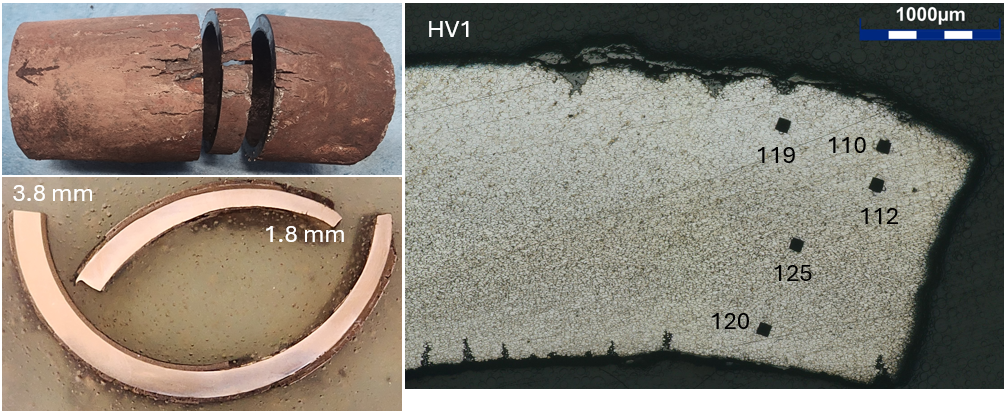

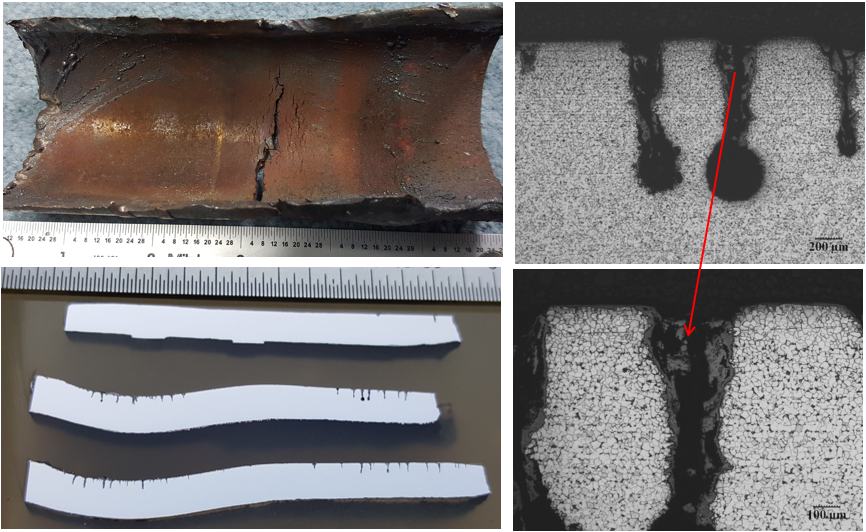

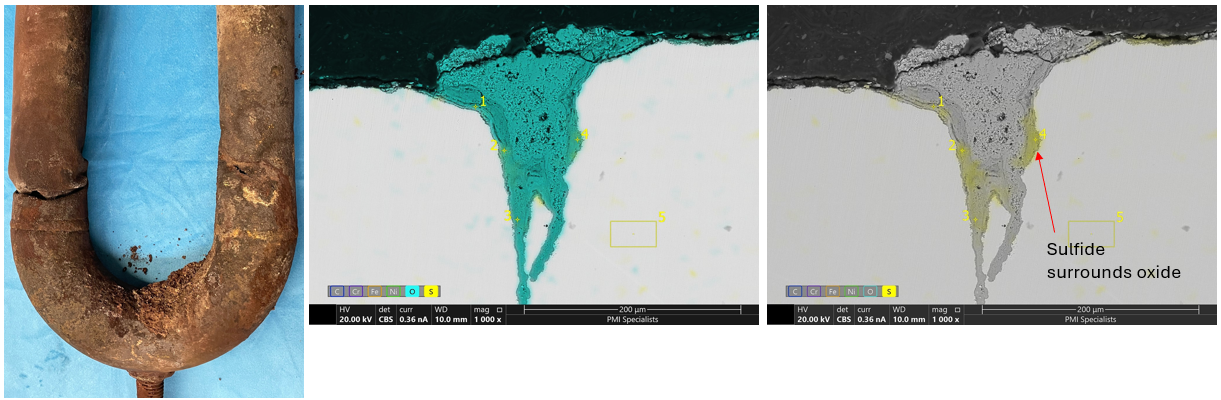

Corrosion-Related Failures

- Waterside (internal) corrosion, such as Oxygen pitting, Acid attack, Caustic gouging under deposits, Hydrogen damage (decarburization from acidic conditions)

- Fireside (external) corrosion, Sulfidation (common with fuel oils and high-sulfur coal), Chloride-induced corrosion, Low-temperature dew point corrosion

Erosion and Erosion-Corrosion

- Fly ash erosion in coal-fired units, especially at bends

- Steam or water impingement in high-velocity regions

- Erosion-corrosion from turbulent flow and corrosive water/steam, often accelerated by oxygen or CO₂ in feedwater

Stress Corrosion Cracking (SCC)

- Chloride SSC (common in austenitic stainless-steel superheater/reheater tubes)

- Caustic SCC (common in boiler water circuits under concentrated caustic deposits)

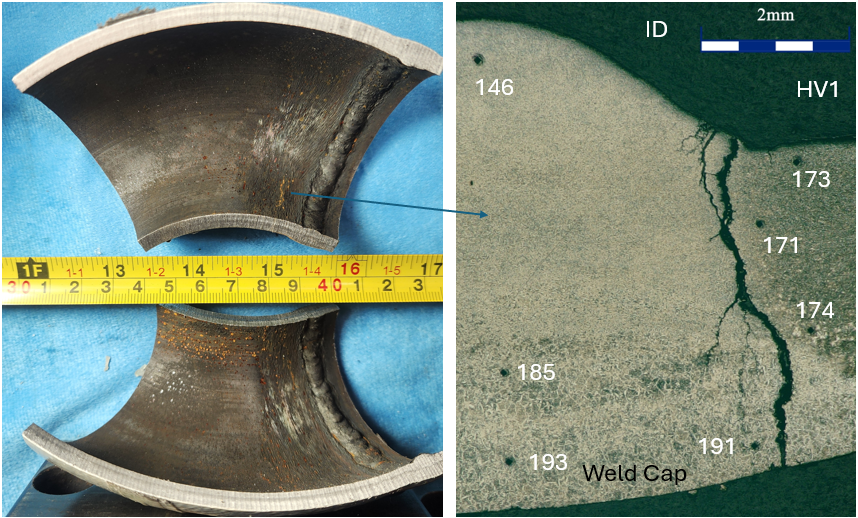

Overheating and Creep Damage

- Long-term exposure to high temperatures causing Microstructural degradation (creep voids, grain boundary damage)

- Tube swelling or bulging

- Rupture at localized hot spots (often from poor heat transfer due to scaling or deposits).

Fatigue and Mechanical Failures

- Thermal fatigue due to frequent start-stop cycles and temperature fluctuations

- Vibration induced fatigue from flow induced vibration or poor support

- Mechanical damage (dents, gouges, improper handling or installation)

Operational and Maintenance Issues

- Poor water chemistry leading to scaling, deposits, or pitting

- Improper startup/shutdown procedures causing thermal stresses

- Inadequate soot blowing or cleaning, leading to localized hot spots

- Weld defects or improper fabrication/repair methods