Failure Analysis

Products do fail, and when they do, the results can be very costly. While failure analysis cannot turn back time and reverse this loss, it can help to prevent future losses. At PMI specialists, we specialize in failure analysis in metal alloys, polymers and ceramics. We will find out if a failure is caused by inappropriate material selection, design, fabrication, operating conditions or some combination. Having knowledge of a failure will give insight on how to improve the performance and longevity of a component, produce, or process and improve overall quality and efficiency.

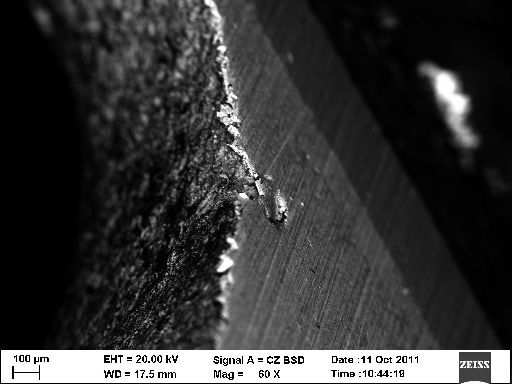

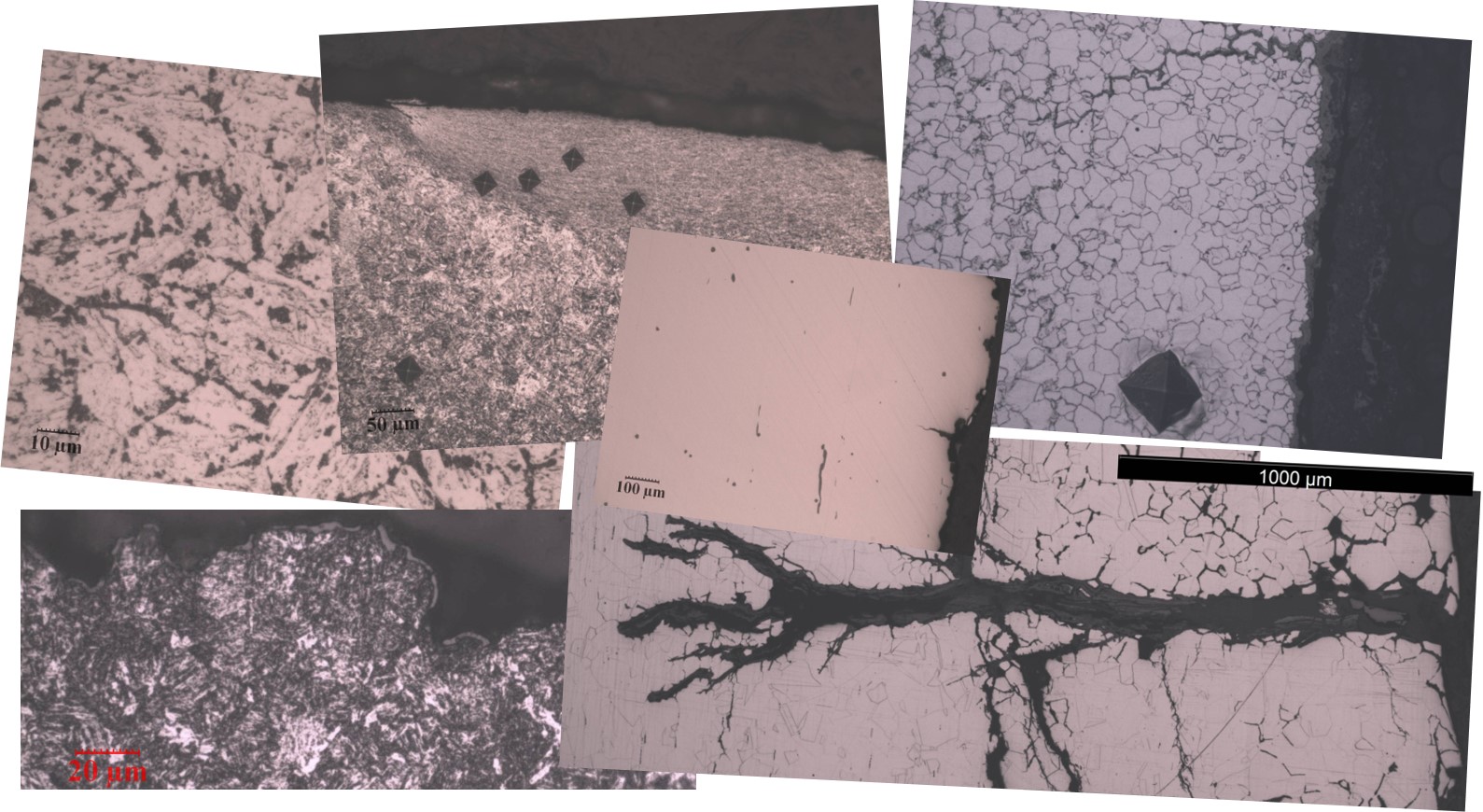

With our state-of-the-art scanning electron microscope (SEM) with SDD energy dispersive x-spectrometry (EDS) detector, and all the latest software and extensive sample preparation methods, PMI specialists is uniquely well-equipped for failure and corrosion investigation.

Every case of failure is different. However, there is a good chance that similar failure had occurred before and reported. PMI specialists has access to tens of thousands of research articles on failure analysis and prevention in addition to the decades of experience in failure analysis. If our experienced PhD-level materials engineers are not enough to diagnose a problem, the failure analysis process at PMI specialists is supported by chemists, finite element analysts and mechanical engineer consultants. No matter what it takes, we will find the cause of your issues.

Some of the components for failure analysis that we look at usually include mechanical equipment; heat exchangers, heater & boiler tubes; pipelines; pumps, pressure vessels; forgings; castings; welds/brazes; tools and dies.

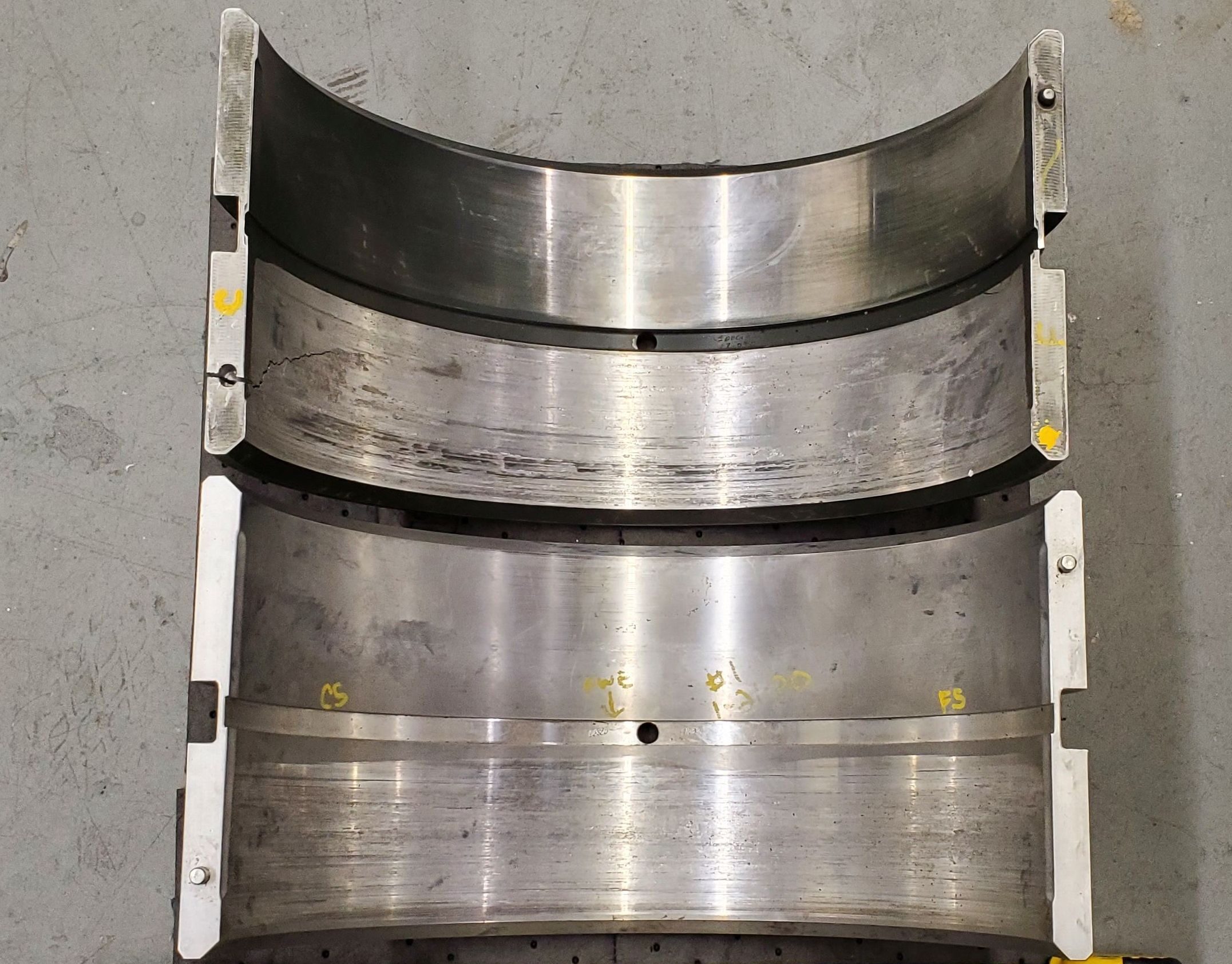

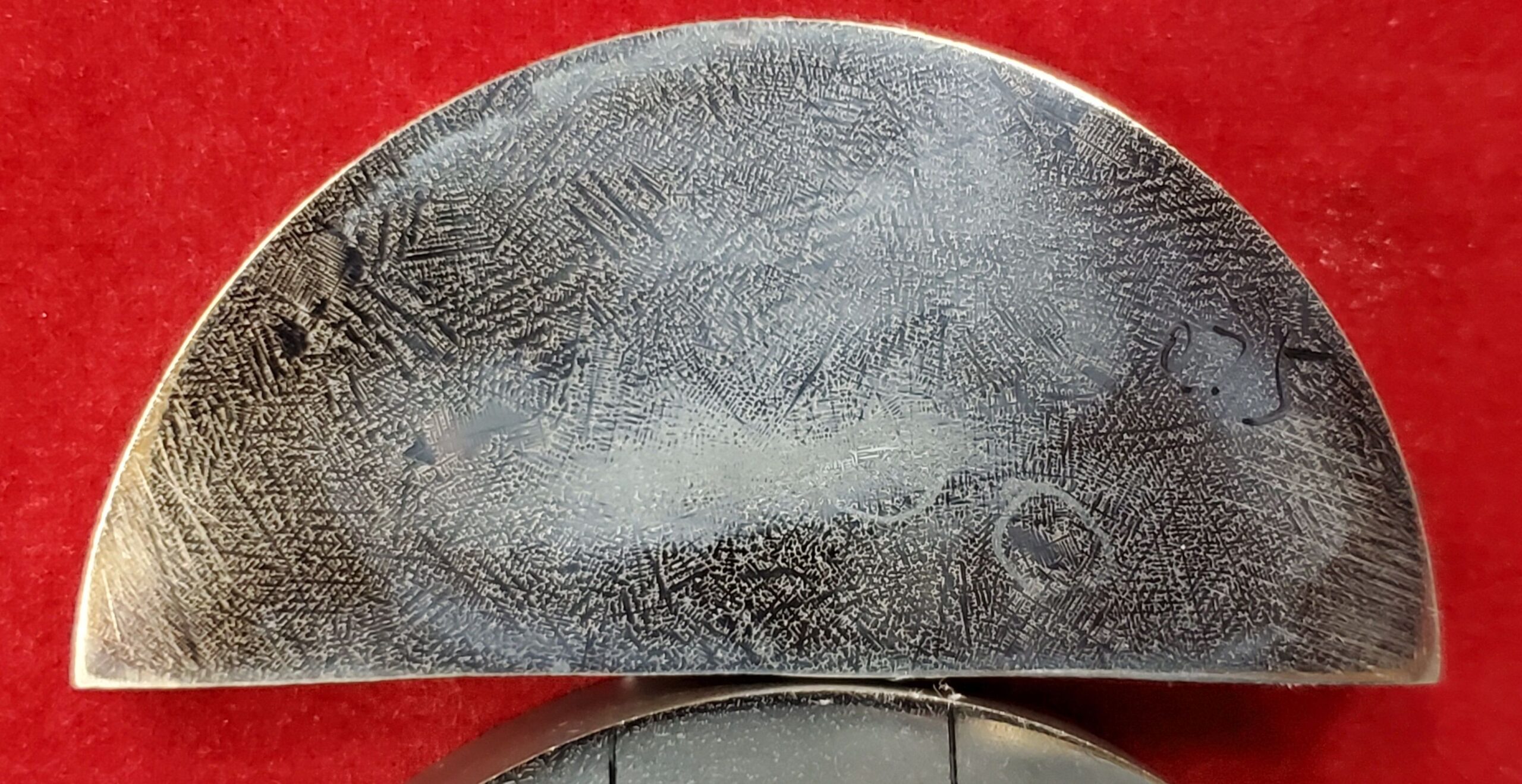

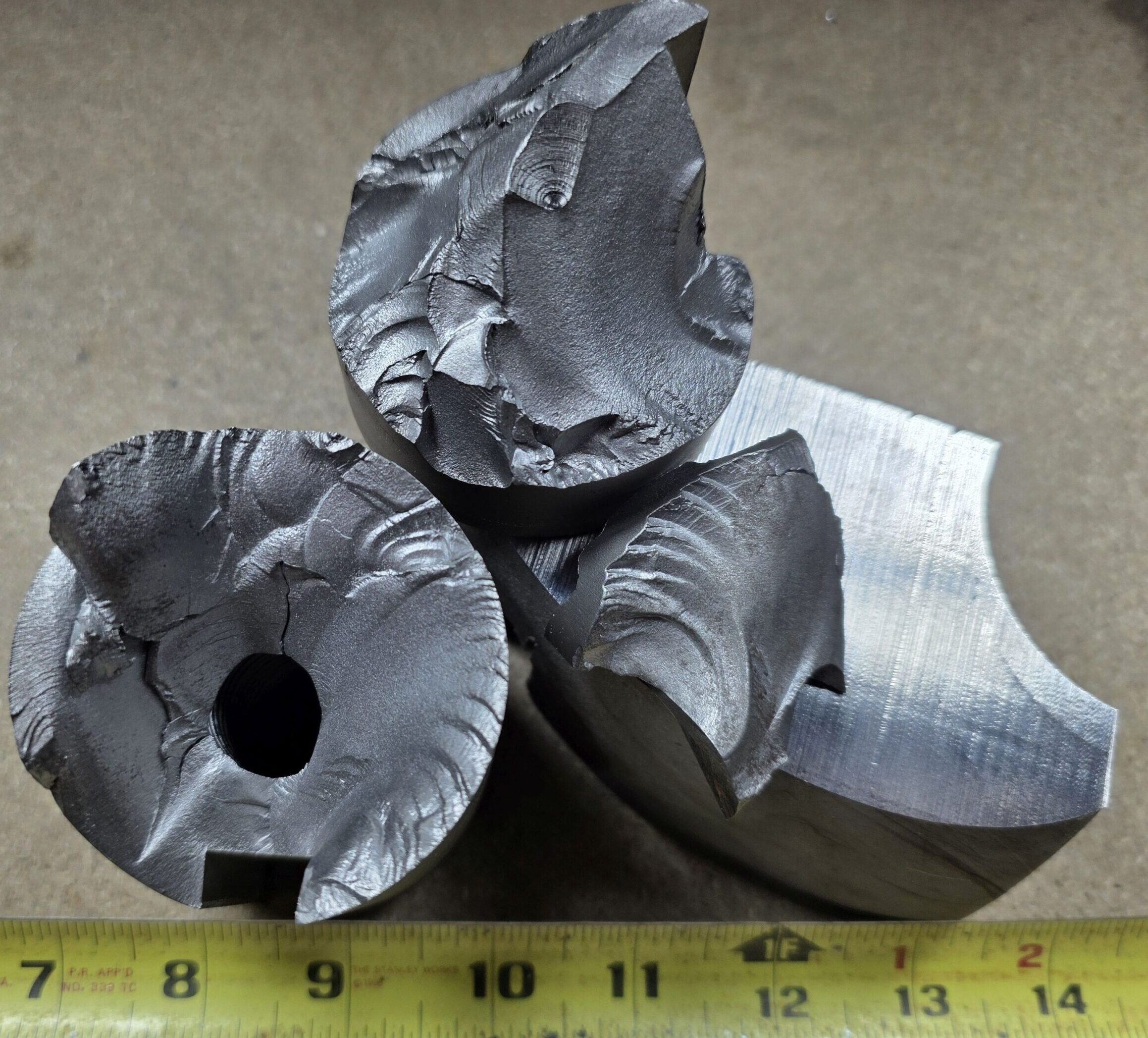

The following pictures are just some examples we have done recently. While the majority of analysis are on common metal and alloys, we have performed many studies on cast iron, Teflon gaskets, Galss liners, Nickel based brazes, Silicon Nitride thermowell sheaths, Zirconia mud pump liners, Oxide dispersed high-temp alloys, Babbit bearings and rare-earth-element-modified Mg alloys, just to name a few.

A 4140 alloy steel shaft in a cooling water pump failed catastrophically after months of high-temperature service. Detailed analysis revealed torsional corrosion fatigue initiating at a keyway fillet with severe pitting, compounded by bolt loosening and cracking due to stress and potential chloride-induced corrosion. Evidence suggested abnormal operating conditions such as vibration or reverse rotation contributed to the failure.

A 1″ carbon steel pipe spool from an offshore crude oil facility leaked due to severe pitting corrosion on the elbow’s intrados. Investigation revealed that trapped water and chlorides, combined with intermittent flow, promoted localized corrosion aggravated by microbial activity (MIC). Cutting the spool confirmed extensive pitting below a half-penetration fillet weld where water accumulated. To prevent recurrence, proper flushing before idle periods and eliminating stagnant water conditions were recommended.