Fire and Explosion Damage Failure Analysis

Fire and explosion damage can compromise material integrity and lead to catastrophic failures. At PMI Specialists, we perform detailed forensic analysis to determine the root cause of fire or explosion events, including metallurgical evaluation, material degradation, and contamination assessment. Our experts examine microstructural changes, heat-affected zones, and residue deposits to identify the sequence of failure. We also evaluate whether the damage resulted from material defects, design flaws, operational errors, or external conditions. Understanding the cause is key to preventing future incidents, improving safety standards, and ensuring compliance with industry regulations.

A fire occurred inside a 20″ 316L stainless steel wood pyrolysis return pipeline, caused by ignition of low-flash-point vapors and carbon residue. The fire lasted 8–15 minutes, with temperatures exceeding 1300°F, leading to grain coarsening and possible carburization on the internal surface. These changes reduce mechanical strength and pitting corrosion resistance, while sensitization risk increases due to chromium carbide formation. Metallurgical analysis indicates the section below the reducer and area 3 should be replaced, while the thicker pipe above the reducer and elbows can remain in service. Overall, the affected section’s fitness for service is compromised due to structural and corrosion concerns.

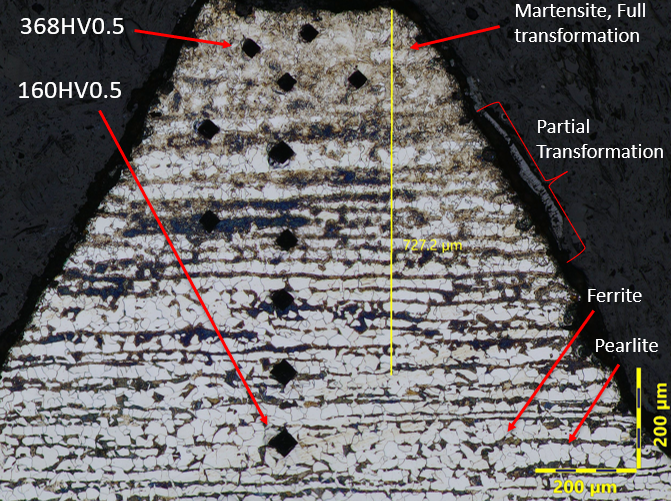

A reciprocating natural gas compressor experienced an internal explosion during a restart after 4,000 hours of operation, caused by oil and air contamination in the gas stream. The third-stage discharge bottle, made of A516-70 steel, bulged as internal pressure likely exceeded 3,000 psi—well above its 2,475 psi hydrotest rating. Metallurgical evidence shows localized heat effects, including martensite formation on coupling threads, indicating temperatures over 1,500°F for a very short duration. The explosion damaged two couplings, fractured a downstream pipe, and partially melted PEEK valve plates, while most steel components remained structurally intact. Thin cooler tubes and plastic parts require replacement, but the bulk compressor assembly was largely unaffected.