Reverse Engineering

Reverse engineering is the process of discovering the technological principles of a device, object or system through analysis of its structure, function and operation. Reverse engineering is often done because the documentation of a particular device has been lost, or the manufacturer who built it is no longer available.

PMI Specialists have expertise in performing reverse engineering on metallic components using several different methods.

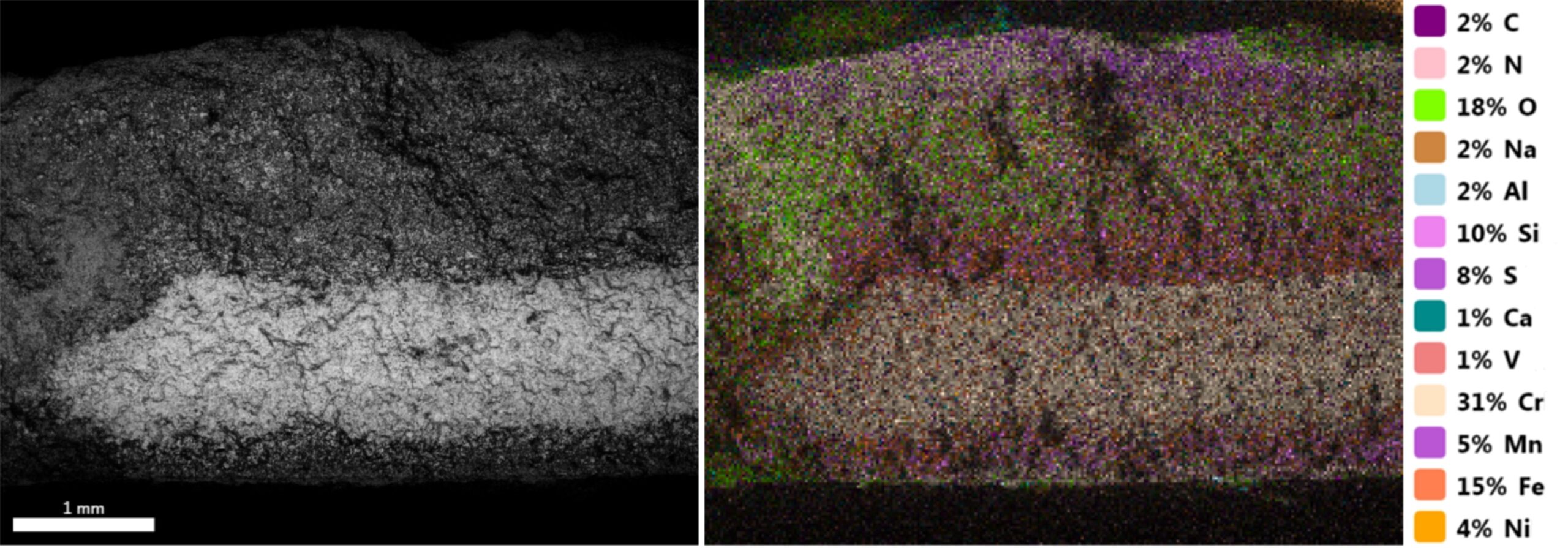

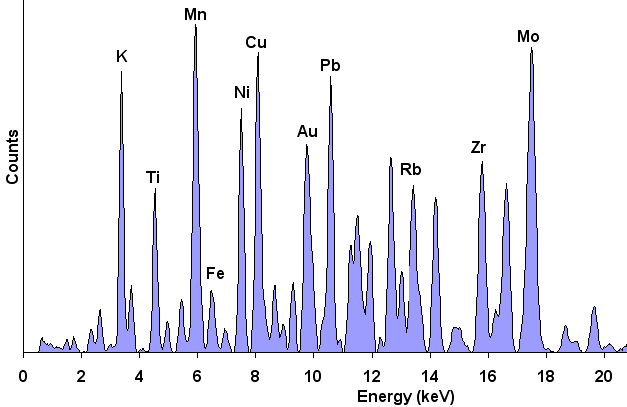

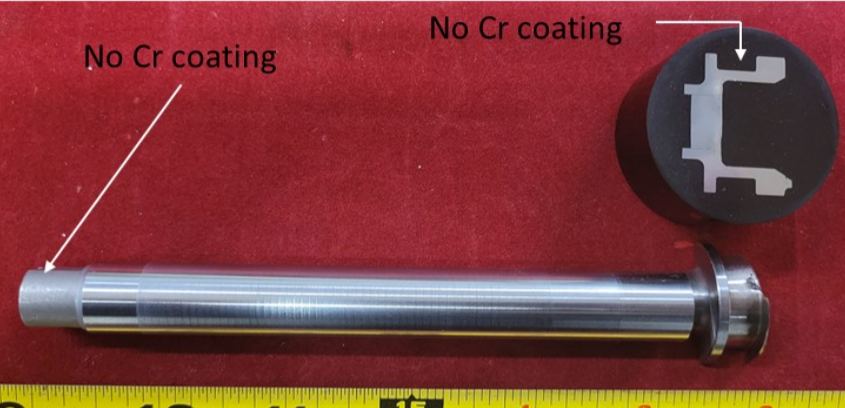

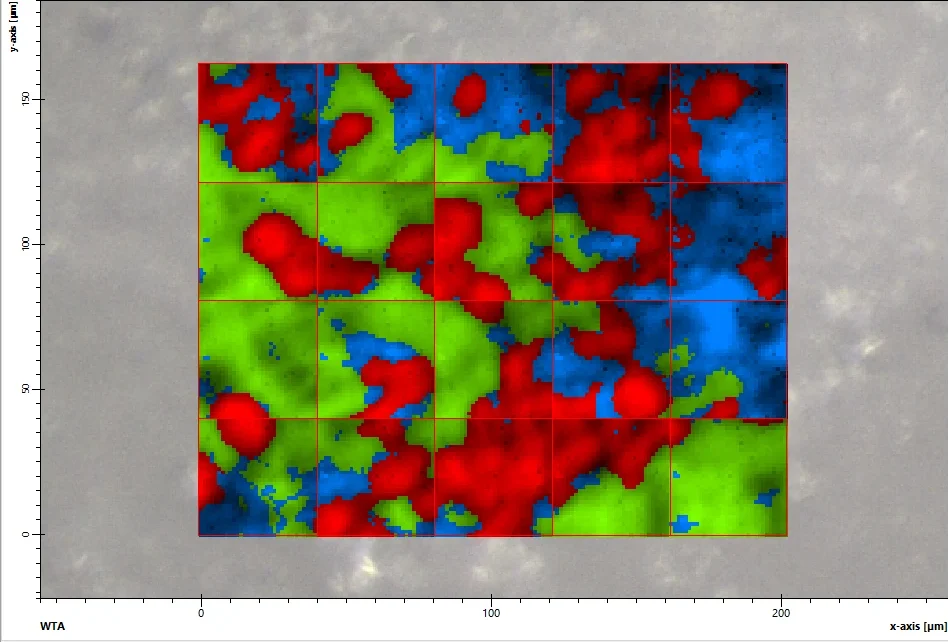

Chemical Analysis

To identify the materials and coatings through either destructive or non-destructive means. We typically use LIBS, XRS, or the SEM with EMS to determine the chemical makeup of an alloy. Our FTIR is used for organic or non-metallic components like plastics or rubbers. After we find what a component is made of, we can move onto other testing to determine the behavior of the material. These tests would include those for carburization and the completion of heat treatment. Coatings and other surface treatments can be identified through several processes. By the time we are done analyzing your component, you will have all the information you need to manufacture an exact replica.

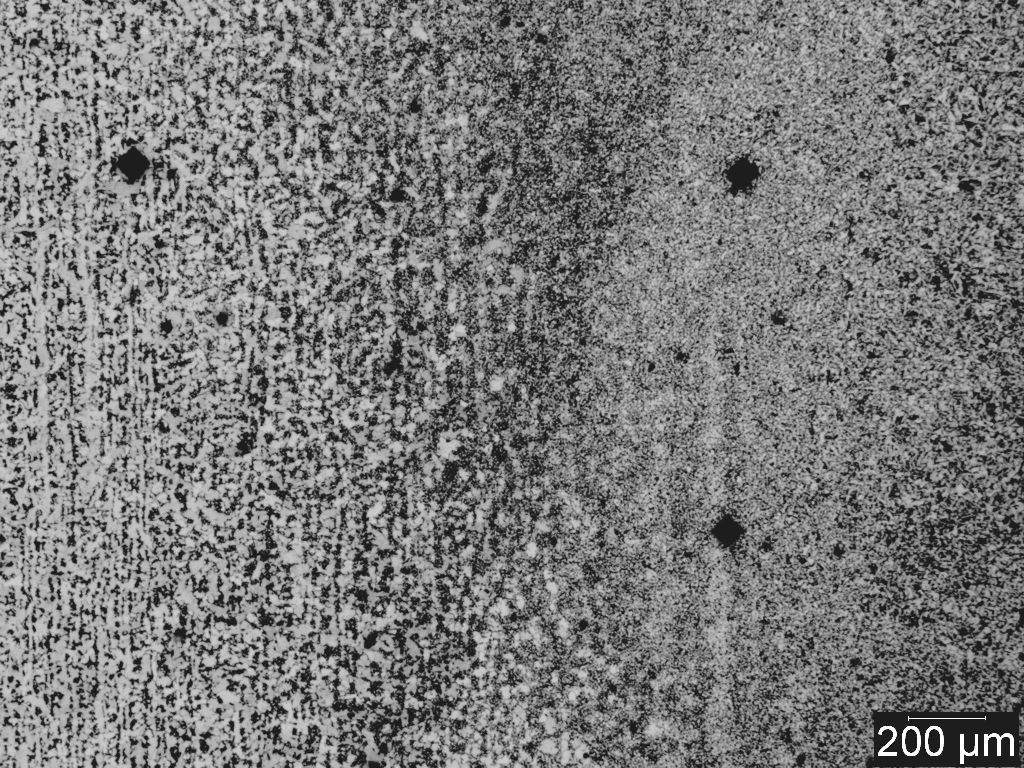

Metallography

The micro structural information can be used to find out if the component is cast, forged, or extruded. In addition, part of the heat treatment information can be gathered. Metallographic analysis can also help determine how the surface is treated, i.e. carburized or nitrided.

Hardness Testing

Hardness testing offers information on how a metallic component is heat treated. Micro hardness testing (Vickers and Knoop) can be performed on cross section of a component to evaluate surface treatment information and the weld heat-affected zone for fine-scale traverses.

Coating Analysis

By combining metallographic, chemical analysis and hardness testing, the type of surface coating can be determined (plating, cladding, anodized, phosphate, conversion coatings, etc.).