Wear Debris Analysis

Wear debris analysis is a powerful tool for monitoring the health of machinery and preventing catastrophic failures. By examining microscopic particles found in system fluids, lubricants, or other sources, we can detect early signs of wear, contamination, or material degradation before major damage occurs. At PMI Specialists, we perform detailed analysis to determine whether debris originates from normal operation, abnormal wear, or failure-related mechanisms such as fatigue, corrosion, or adhesion.

Using advanced techniques including Scanning Electron Microscopy (SEM) with EDS elemental analysis, optical microscopy, and particle morphology evaluation, we identify the wear type, source, and severity. This information helps our clients take proactive measures to extend their equipment’s lifespan.

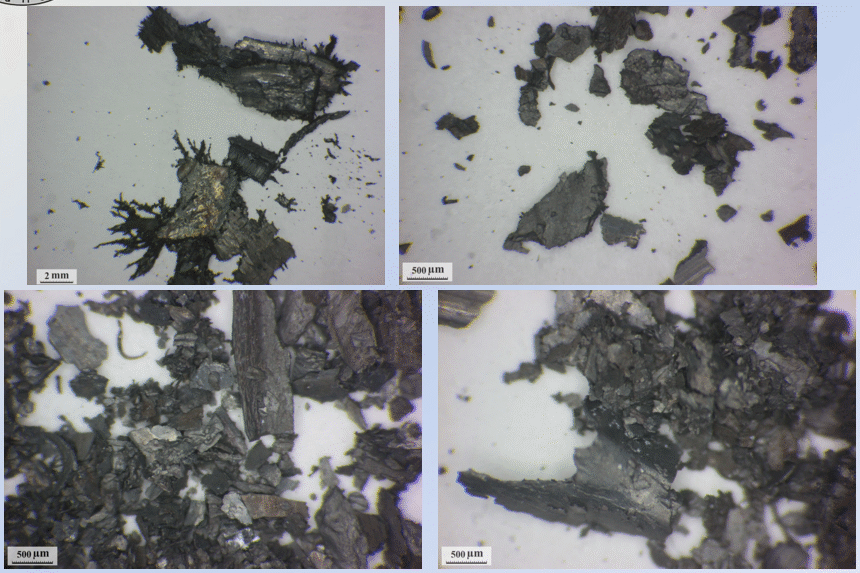

Metal debris was collected from downstream of a polystyrene extruder after an unknown malfunction. XRF analysis showed higher chromium and molybdenum levels than typical for standard extruder steels such as 4140 or F22, suggesting the debris could originate from multiple sources. The most probable cause is severe abrasion between a nitrided 4140 screw and hard contaminants or additives in the polymer under high pressure.

A small bag of metal debris was collected from downstream of a polystyrene extruder, indicating a malfunction in the equipment. Analysis shows the debris originates from several components:

- Bolt: High-strength carbon steel, Zn coated, typical of structural bolts.

- Aluminum piece: Made from a common 6063-type aluminum alloy.

- Partial ring: Stainless steel retainer ring, precipitation-hardened type, consistent with high-hardness applications.

- Pipe debris: Mostly from X52/X60-grade steel, with minor variations in alloying elements.

Overall, the debris reflects material wear and failure from multiple components within the system, helping to pinpoint potential sources of malfunction.