Automated Ball Indentation

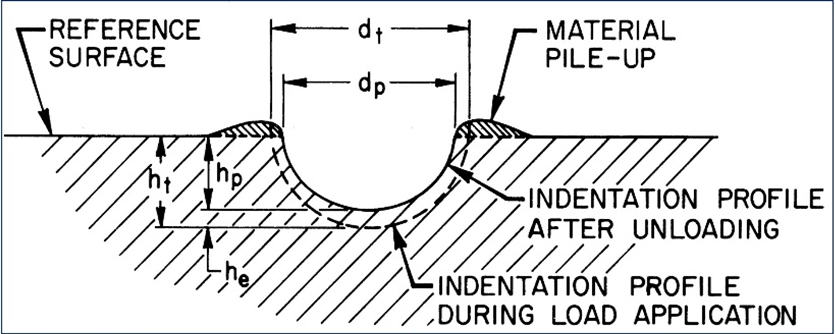

Automated Ball Indentation (ABI®) is a proven technology which makes the non-destructive measurement of Yield Strength, Ultimate Tensile Strength of all metals and Fracture Toughness (on Ferritic Steels) possible. It was first developed by Fahmy Haggag from Oak Ridge National Lab for applications within the nuclear industry.

ABI® even allows for the pipeline to continue its normal operation while undergoing analysis. There is no need to pause your work for us to do ours.

We own two of the 30 existing ABI testers in the world and use them extensively on all types of pipes and pipelines. Because of this, PMI Specialists’ ABI® technician team is the most qualified on earth. No one is better suited to complete your Mega Rule mandated pipeline analysis than PMI Specialists.

ABI® can determine the following mechanical properties of a metal without the need to cut samples.

- Yield strength

- Ultimate tensile strength

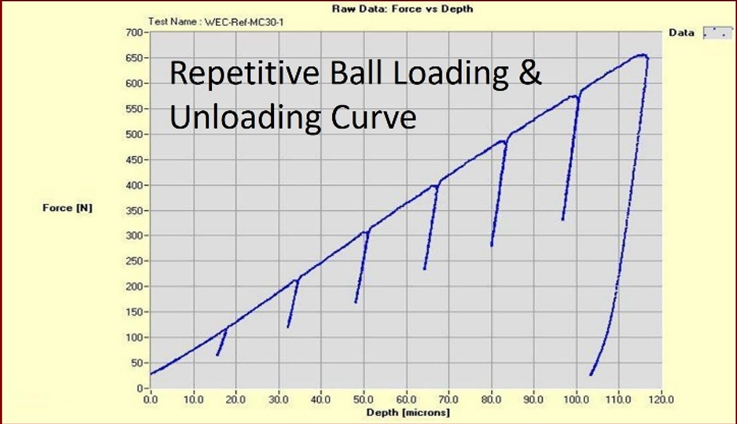

- Strain-hardening exponent (n)

- Strength coefficient (k)

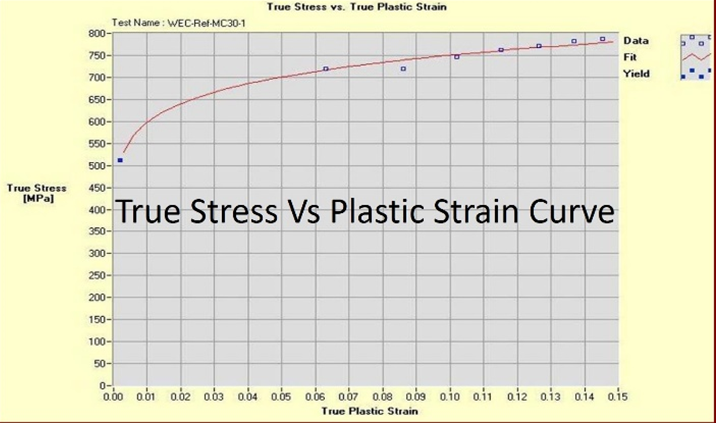

- True-plastic stress-strain curve

- Uniform ductility

- Maximum Allowable Operating Pressure (MAOP)

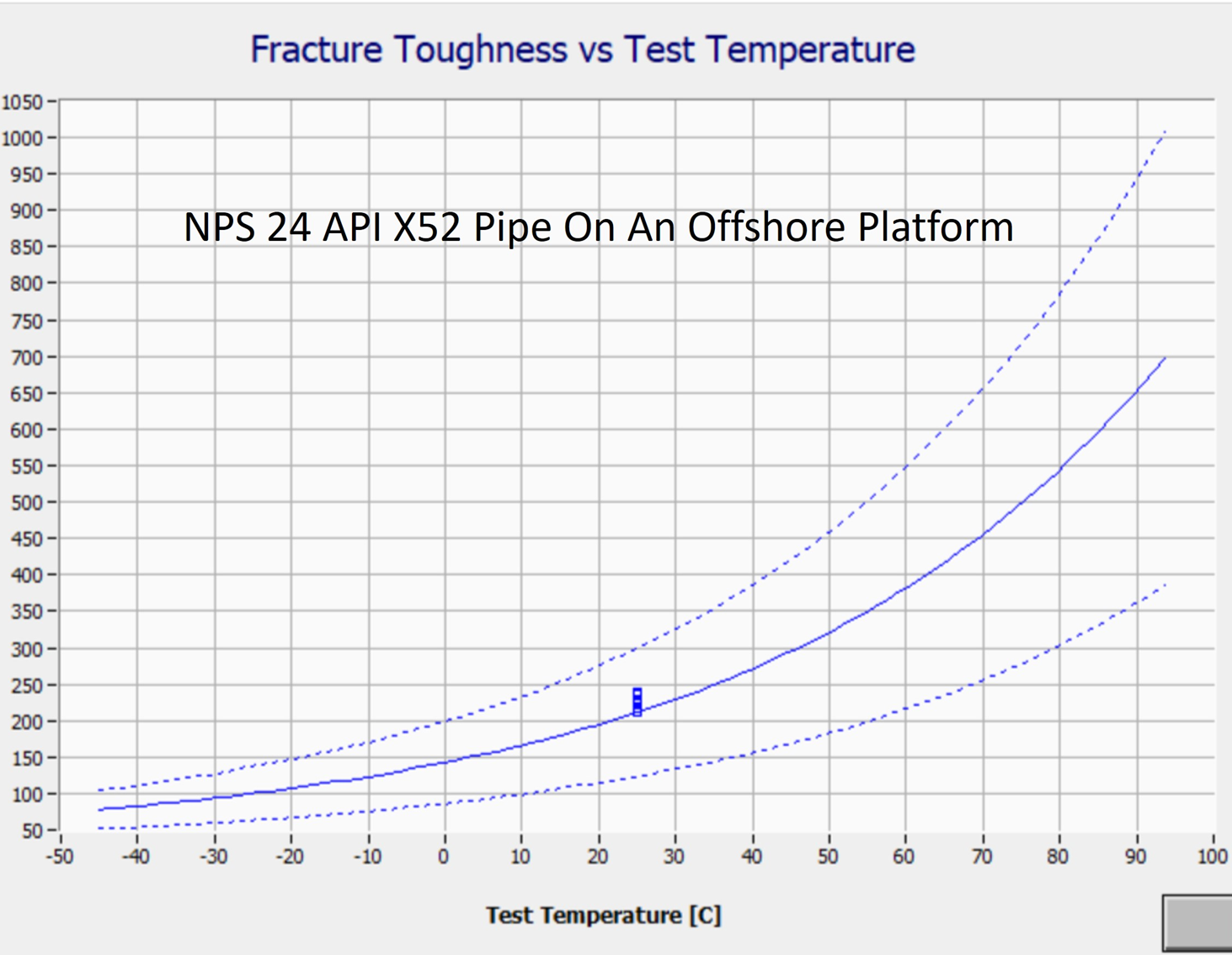

- Fracture toughness on ferritic steels

- Fracture master curve analysis on ferritic steels

- Reference temperature on ferritic steels

ABI® testing has been successfully used on oil/gas pipelines, pressure vessels, automotive frames, airplane parts, forgings, coke drums and offshore platforms to determine the mechanical properties that are lost due to missing documents or lack of testing. It can also be used for some properties that are unable to achieve by conventional testing method. For example: yield strength on small objects, weld heat affected zones, or fracture toughness on thin sheet metals.