Metallographic Examination

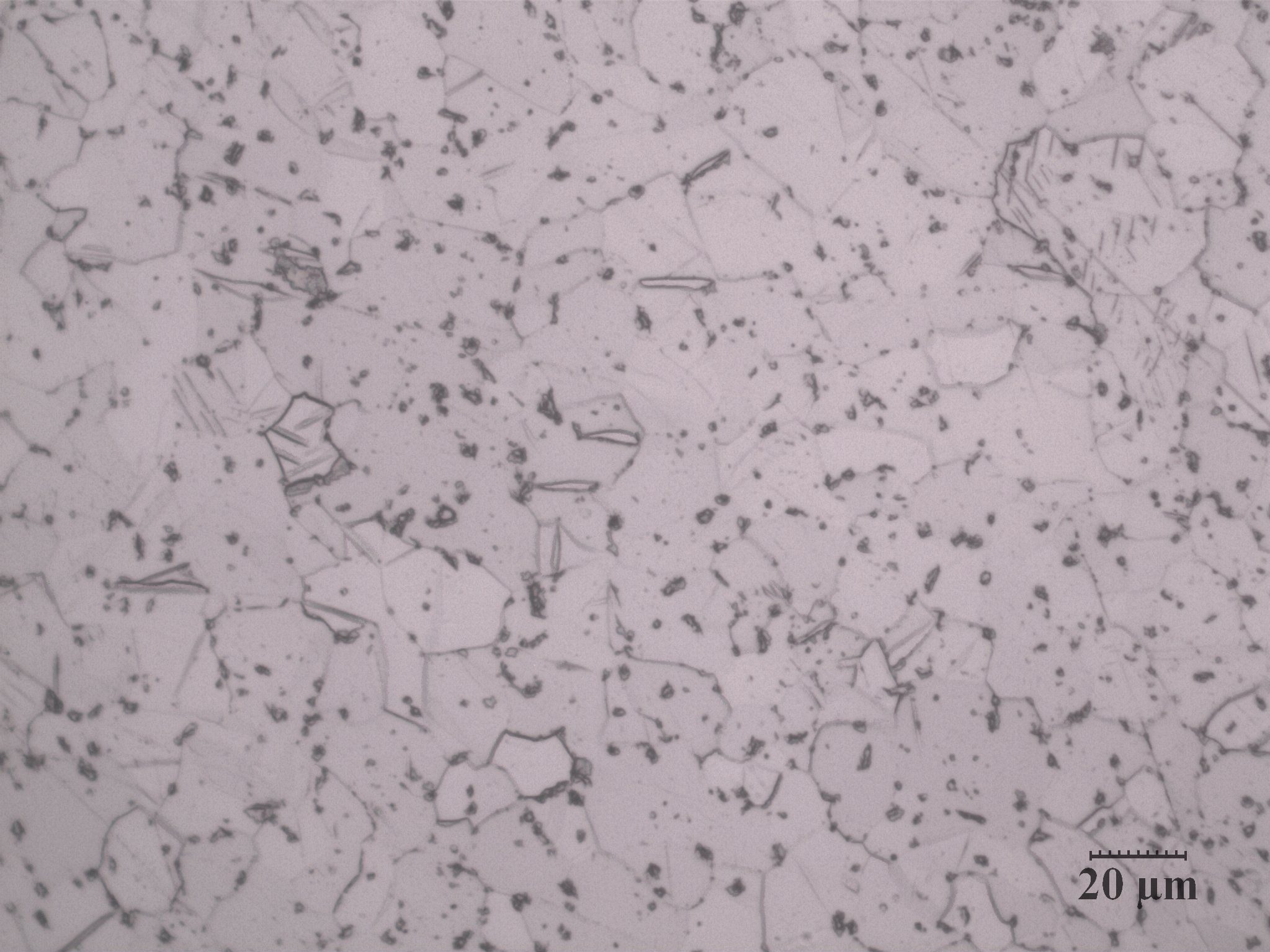

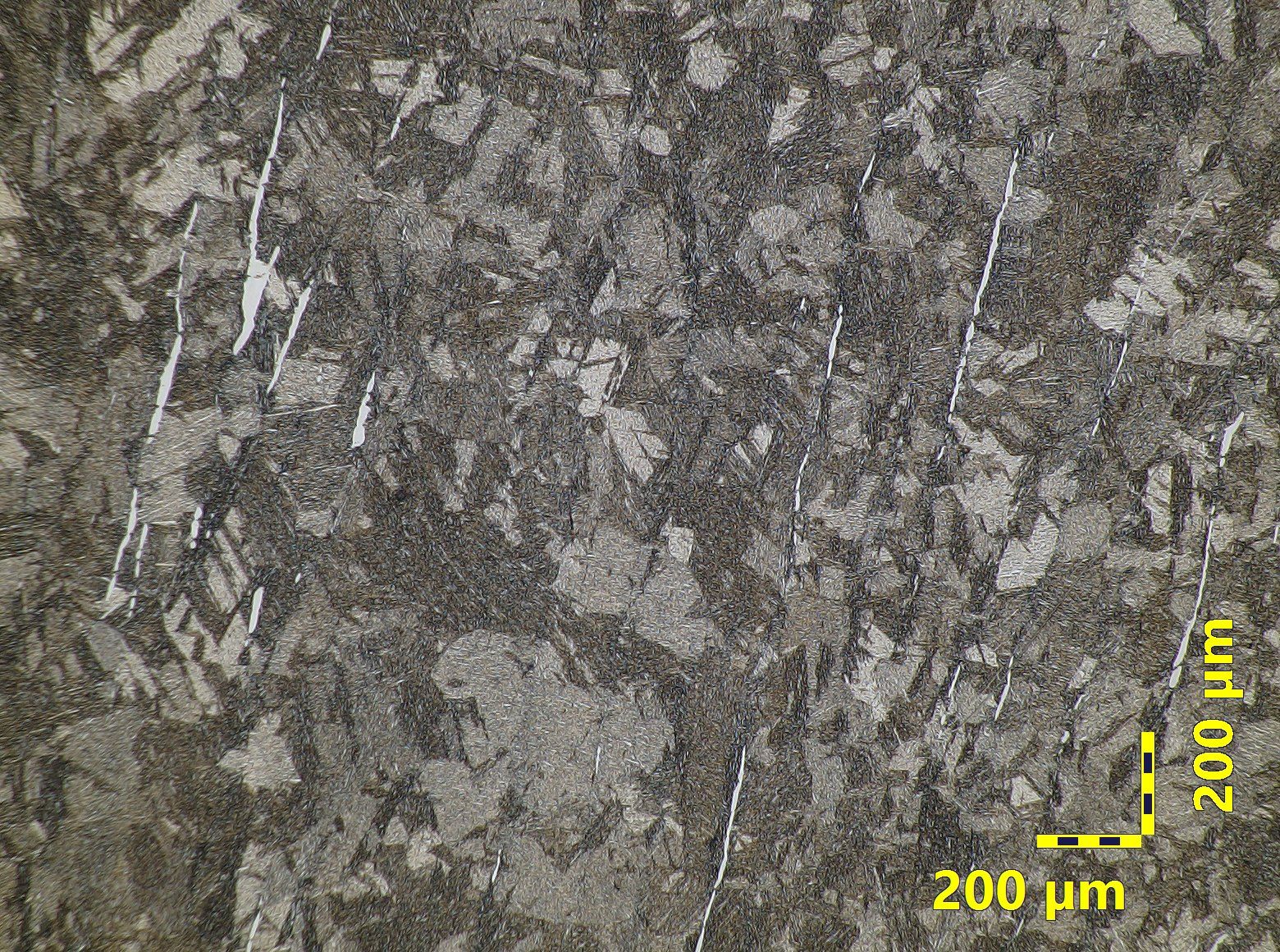

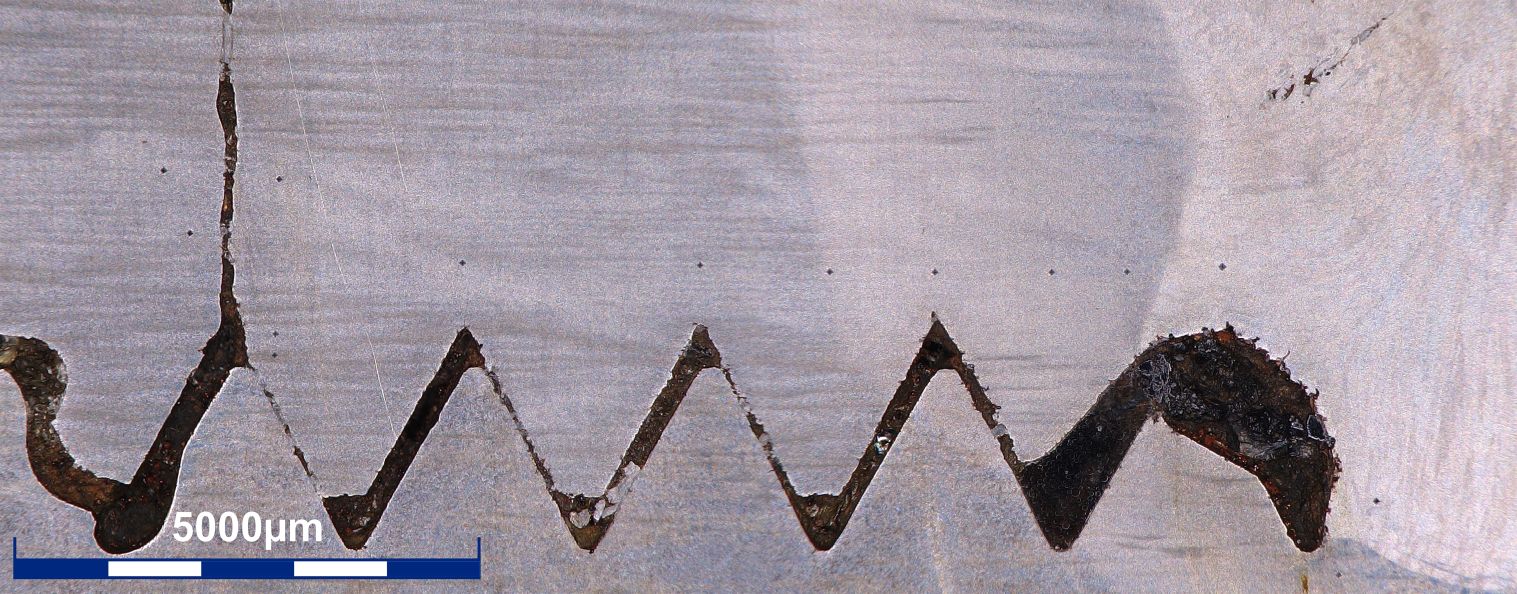

Metallographic examination is the systematic study of a metal’s microstructure to assess its manufacturing quality, service performance, and failure mechanisms. This process involves sectioning, mounting, precision grinding, polishing, and etching to reveal structural details, followed by optical or electron microscopy. Through this analysis, we evaluate grain size, phase distribution, cleanliness (inclusions), heat treatment effects, and signs of degradation such as cracking, corrosion, or embrittlement. Our expertise ensures accurate interpretation of microstructural features, providing engineers with the insights needed for root cause analysis, process validation, and metal conformance to specifications.

To support our metallographic analysis, we use a full range of advanced techniques and instruments to deliver accurate and detailed results. Our process begins with careful sample preparation, including precision sectioning, mounting, grinding, and polishing, followed by etching to reveal key structural features. For imaging, we utilize high-resolution optical and 3D digital microscopes for grain structure analysis and defect characterization. When higher magnification or elemental analysis is required, we perform scanning electron microscopy (SEM) with energy-dispersive spectroscopy (EDS) to identify microstructural features and chemical composition. We also conduct hardness testing, to evaluate mechanical properties and verify heat treatment conditions. Combined with image analysis and advanced data interpretation, these tools ensure a comprehensive evaluation of material integrity and failure modes.

Our Metallographic Capabilities

- ASTM Grain Size Analysis

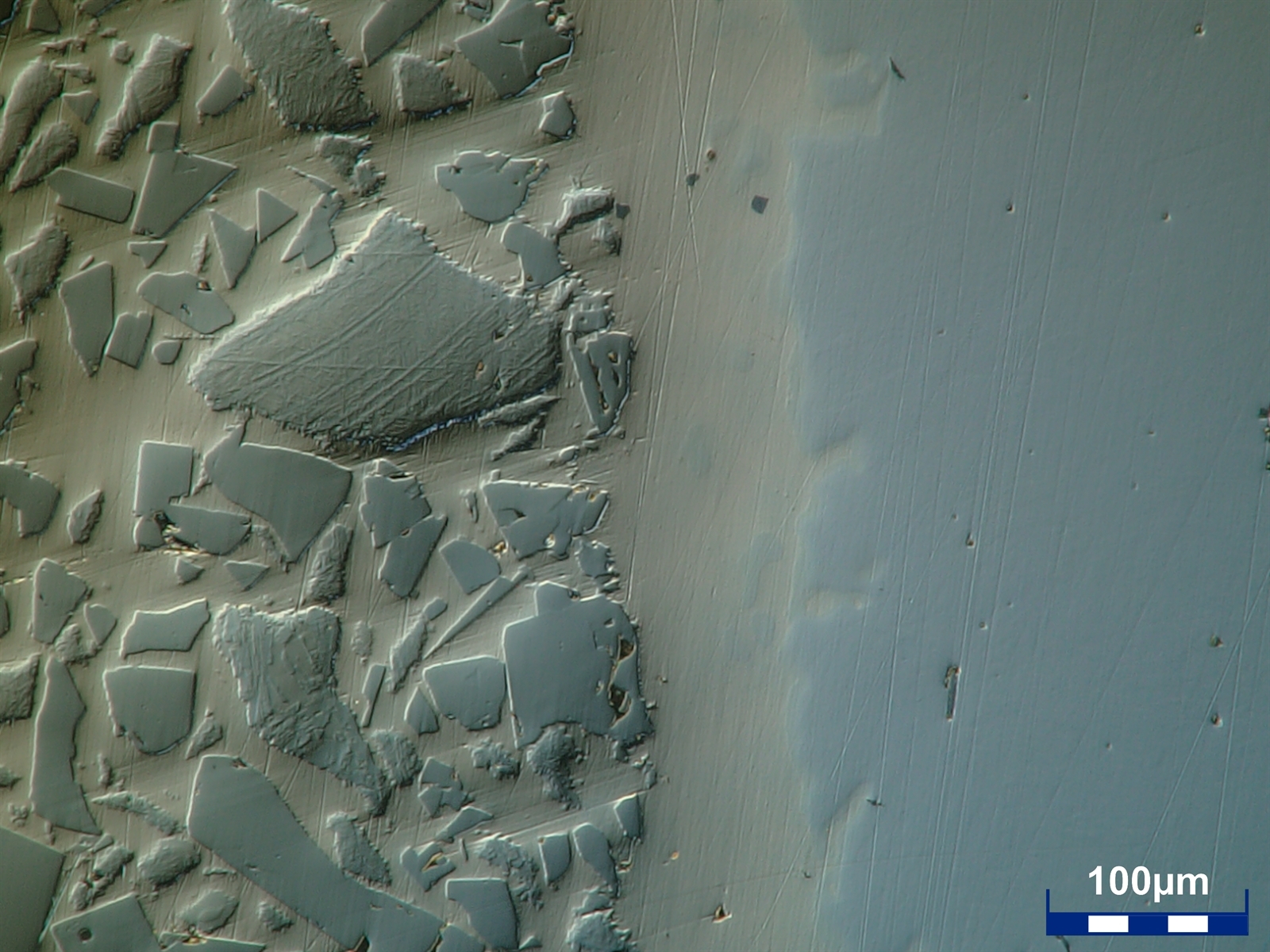

- Particle Size and Distribution

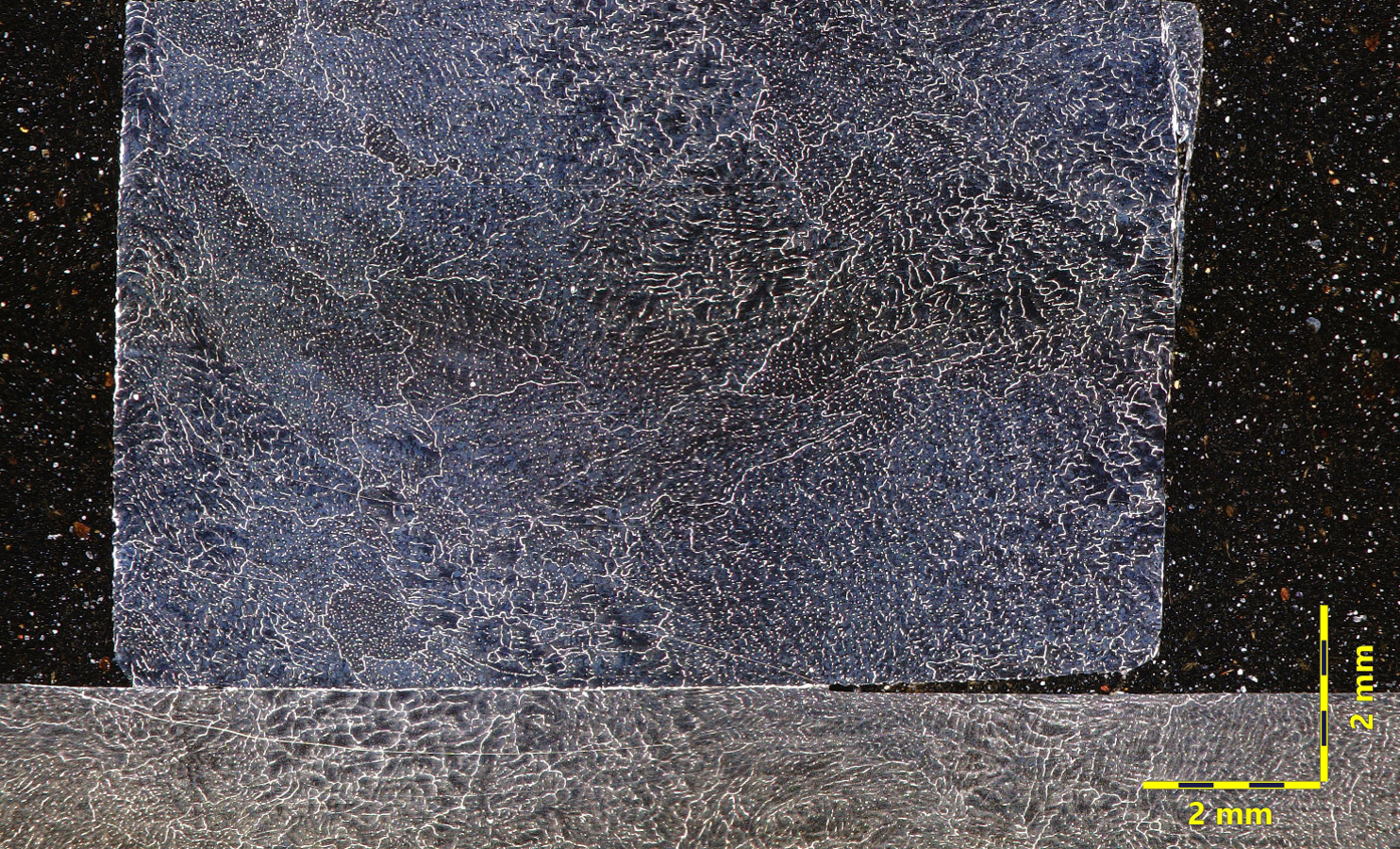

- Coating Thickness Measurement

- Case Depth Measurement (Carburized, Nitrided, etc.)

- Ferrite/Pearlite Quantification

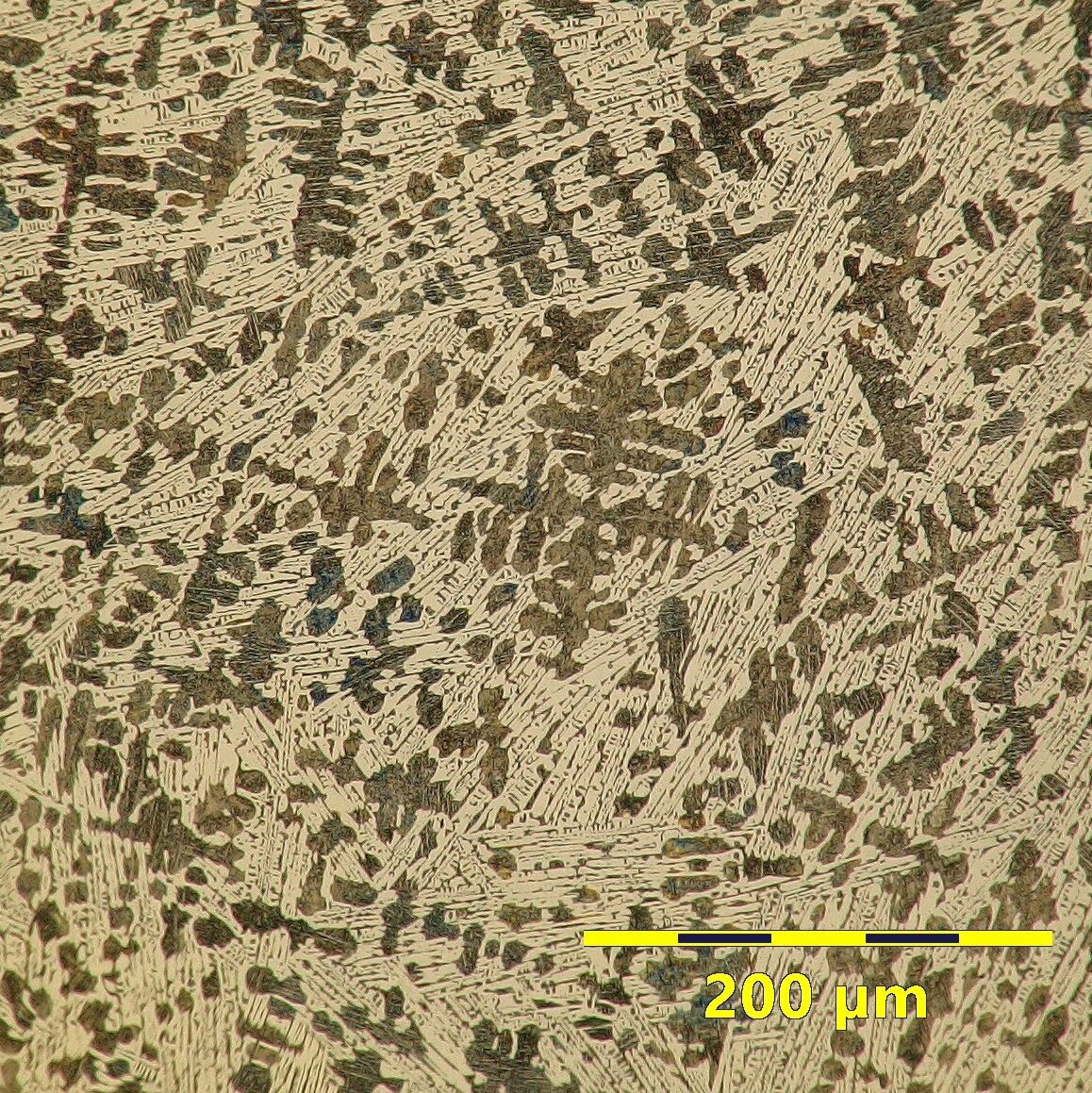

- Bainite, Martensite, Delta Ferrite, and Retained Austenite Identification

- Duplex and Multi-phase Alloy Structure Analysis

- Phase Area Analysis

- Phase Transformation Verification

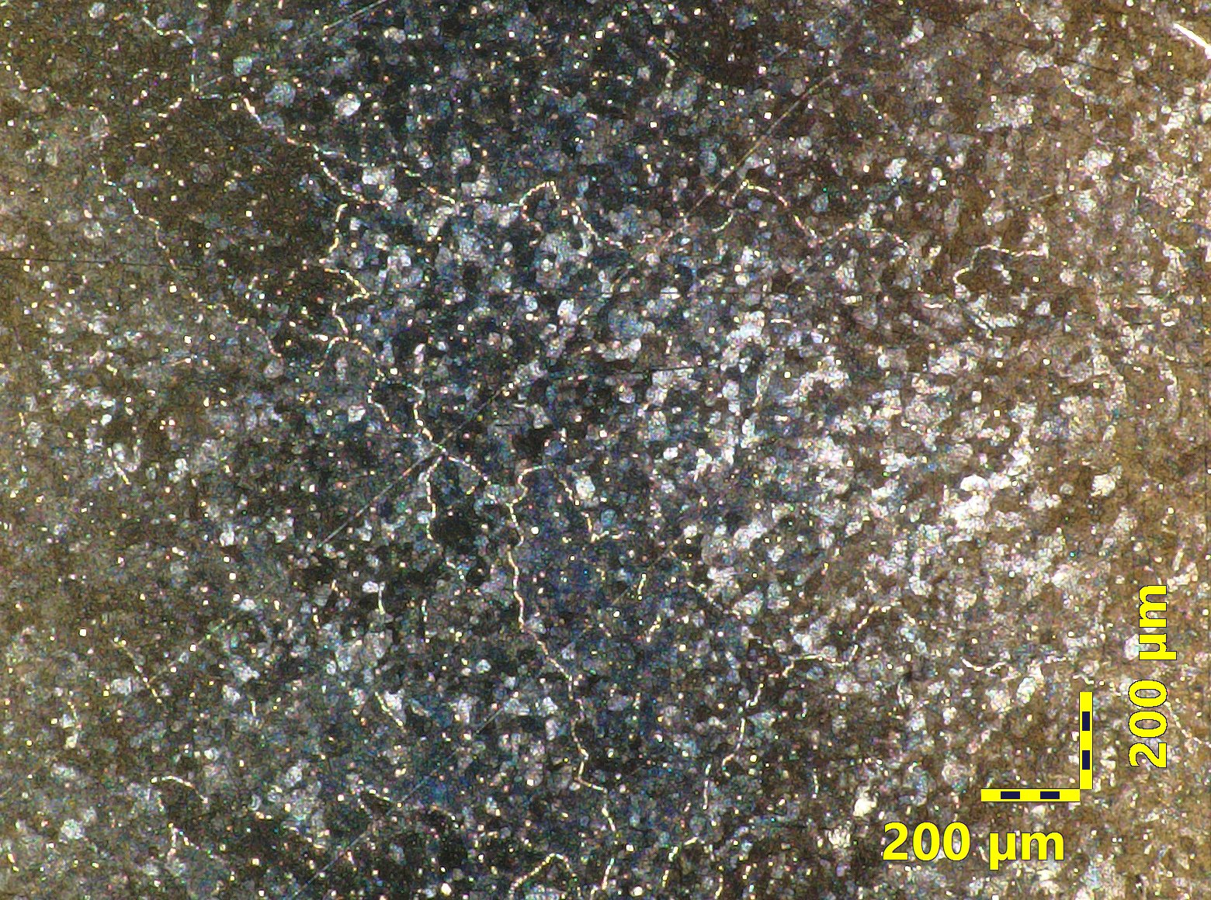

- Porosity Measurement

- Carbide Precipitation and Sensitization Detection

- Nodularity Evaluation

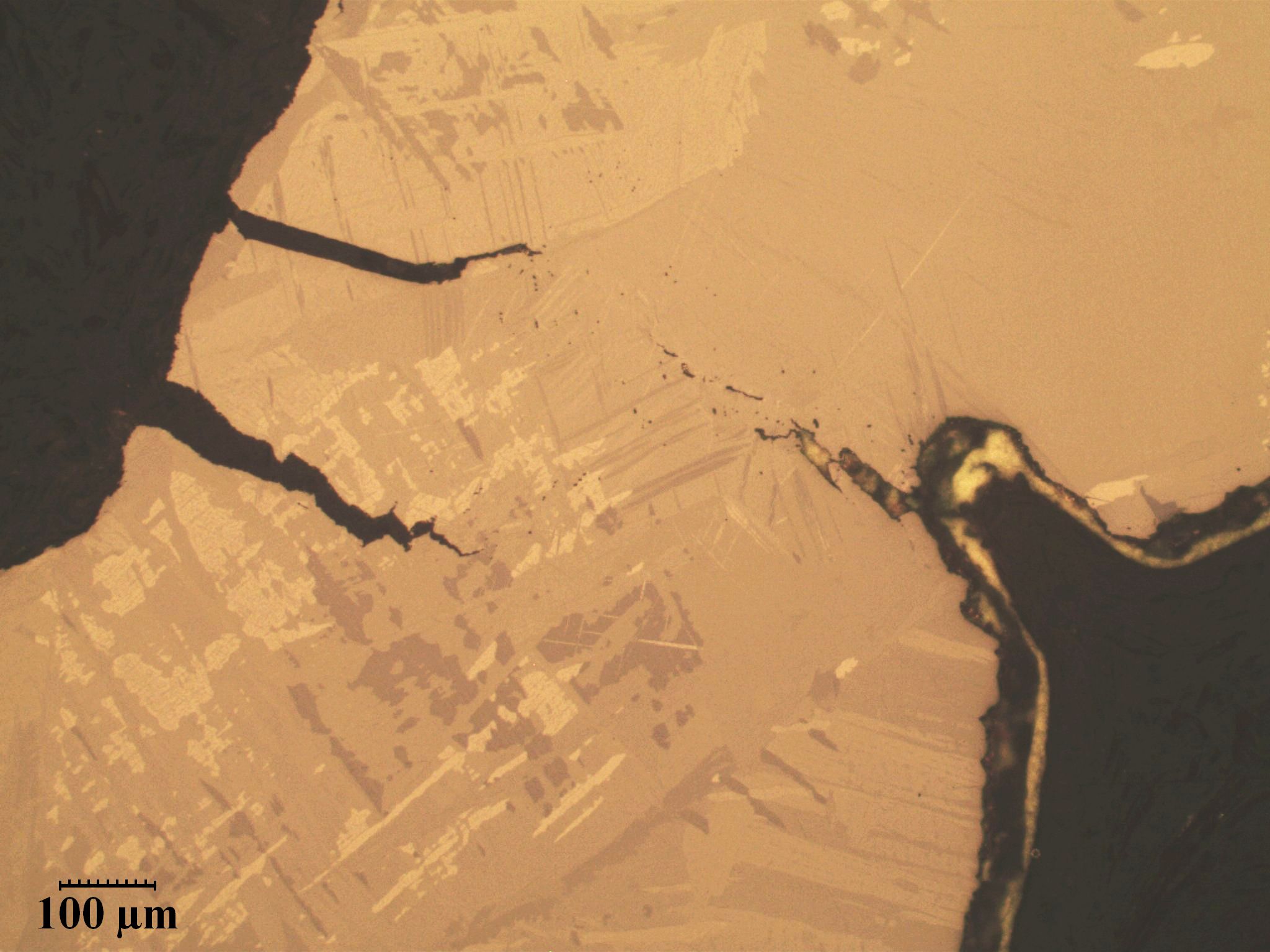

- Intergranular Corrosion Attack

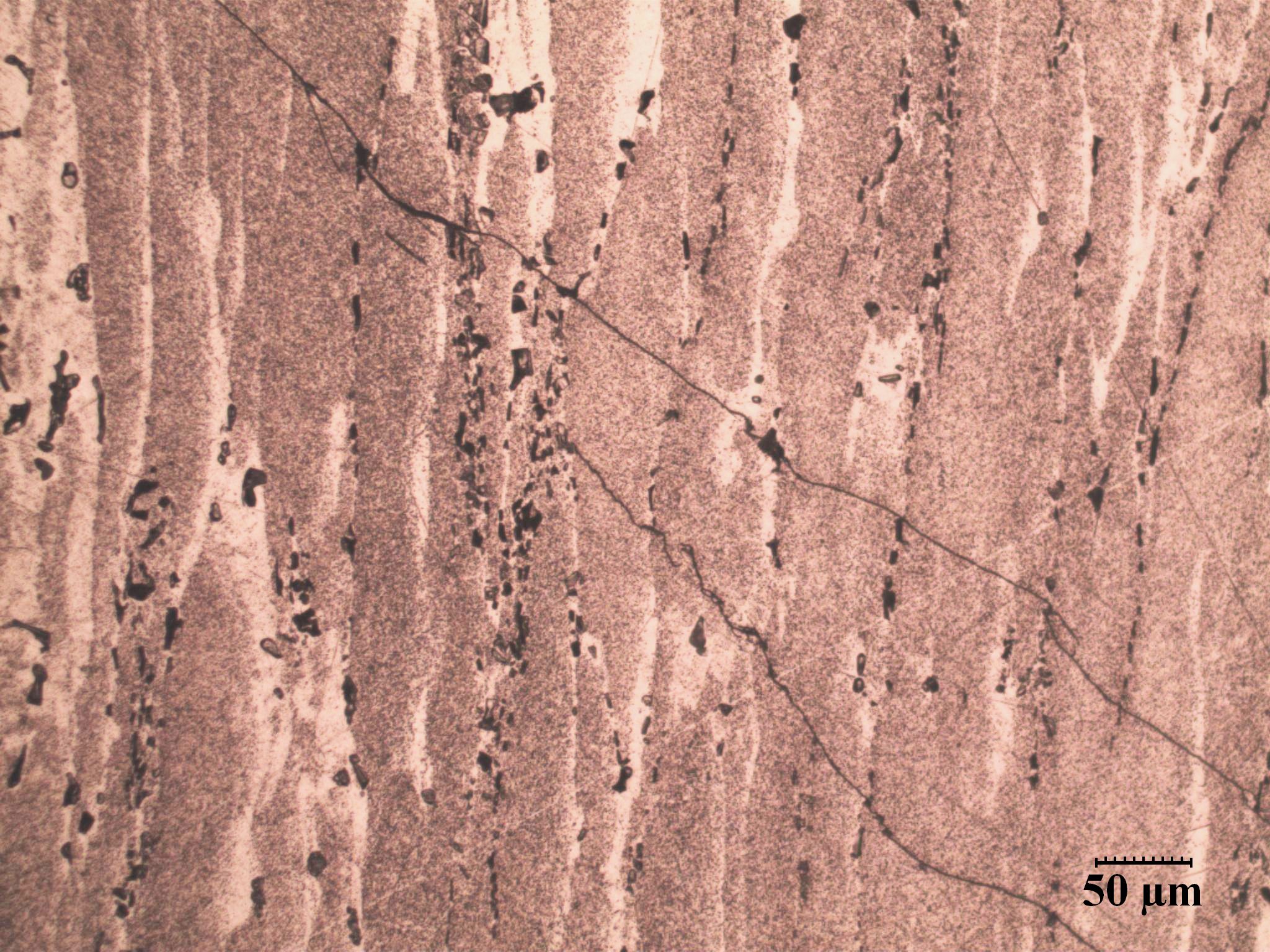

- Segregation and Banding Assessment

- Surface Contamination and Oxide Scale Analysis

- Weld Microstructure Evaluation

- Weld Defect Identification (Inclusions, Porosity, Cracks)

- Casting Defect Identification (Shrinkage, Porosity, Inclusions)

- Fracture Surface Examination

- Micro-cleanliness/Micro-inclusion Rating

- Intergranular Attack Detection

- Graphite Flake Size Classification

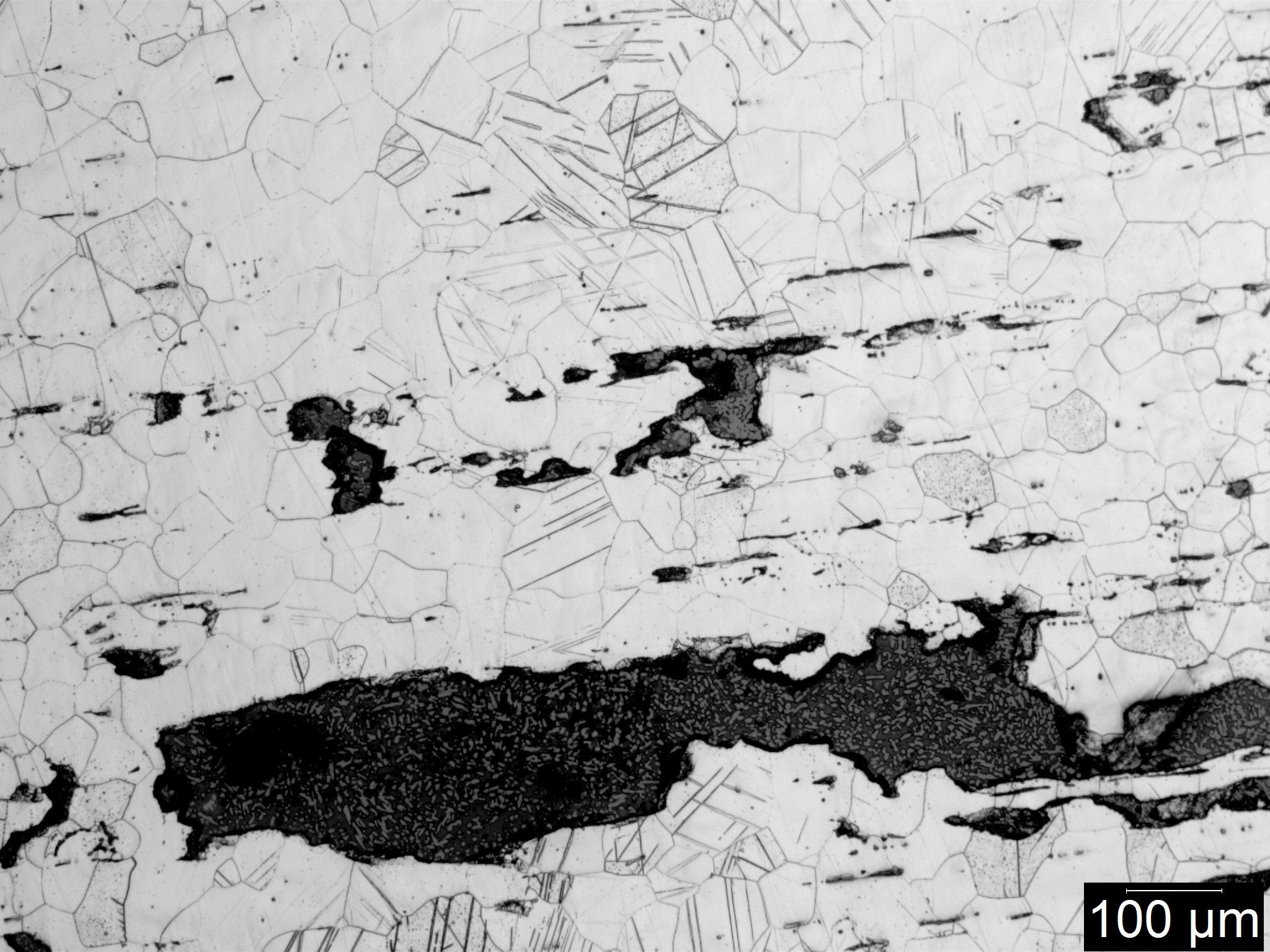

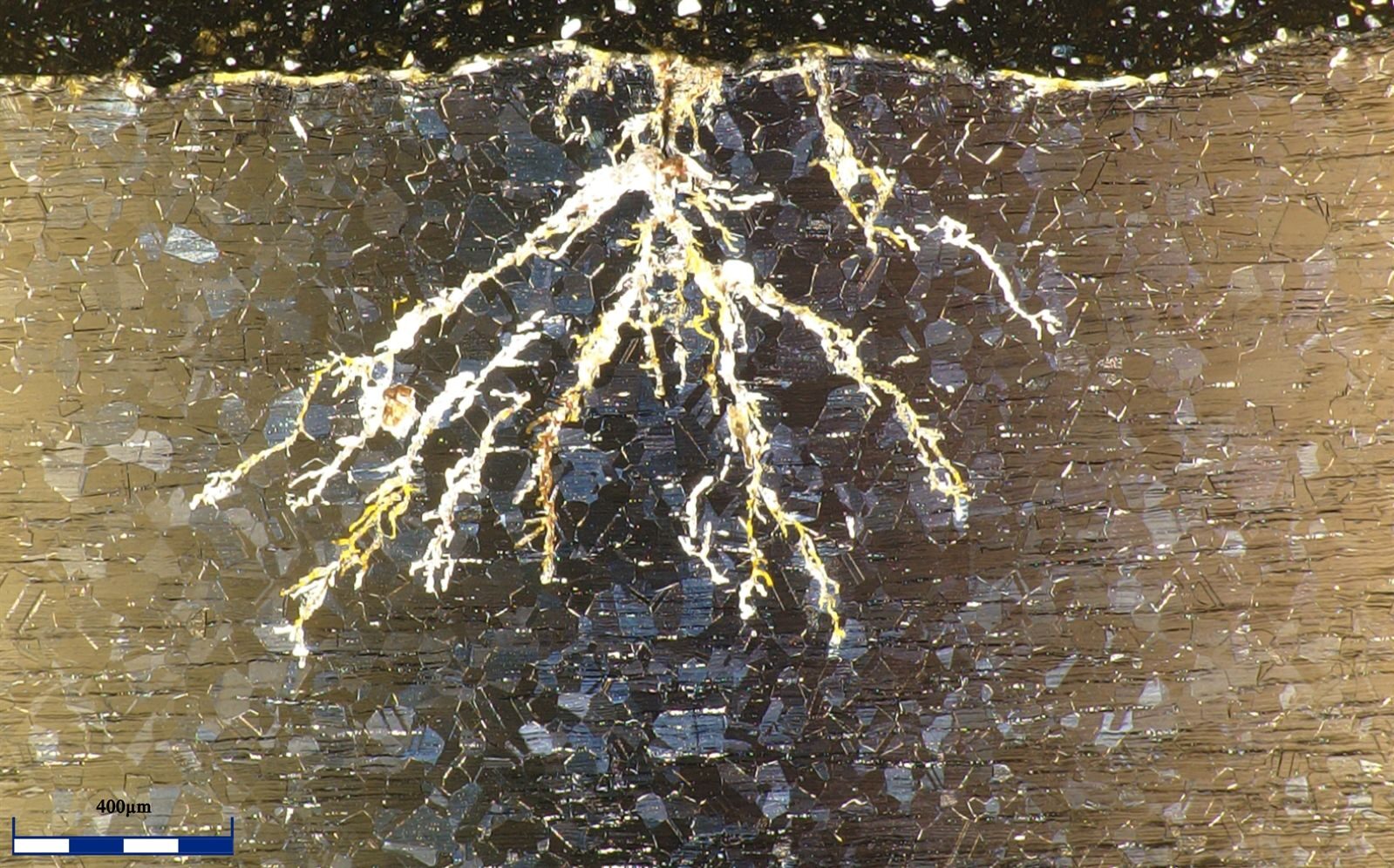

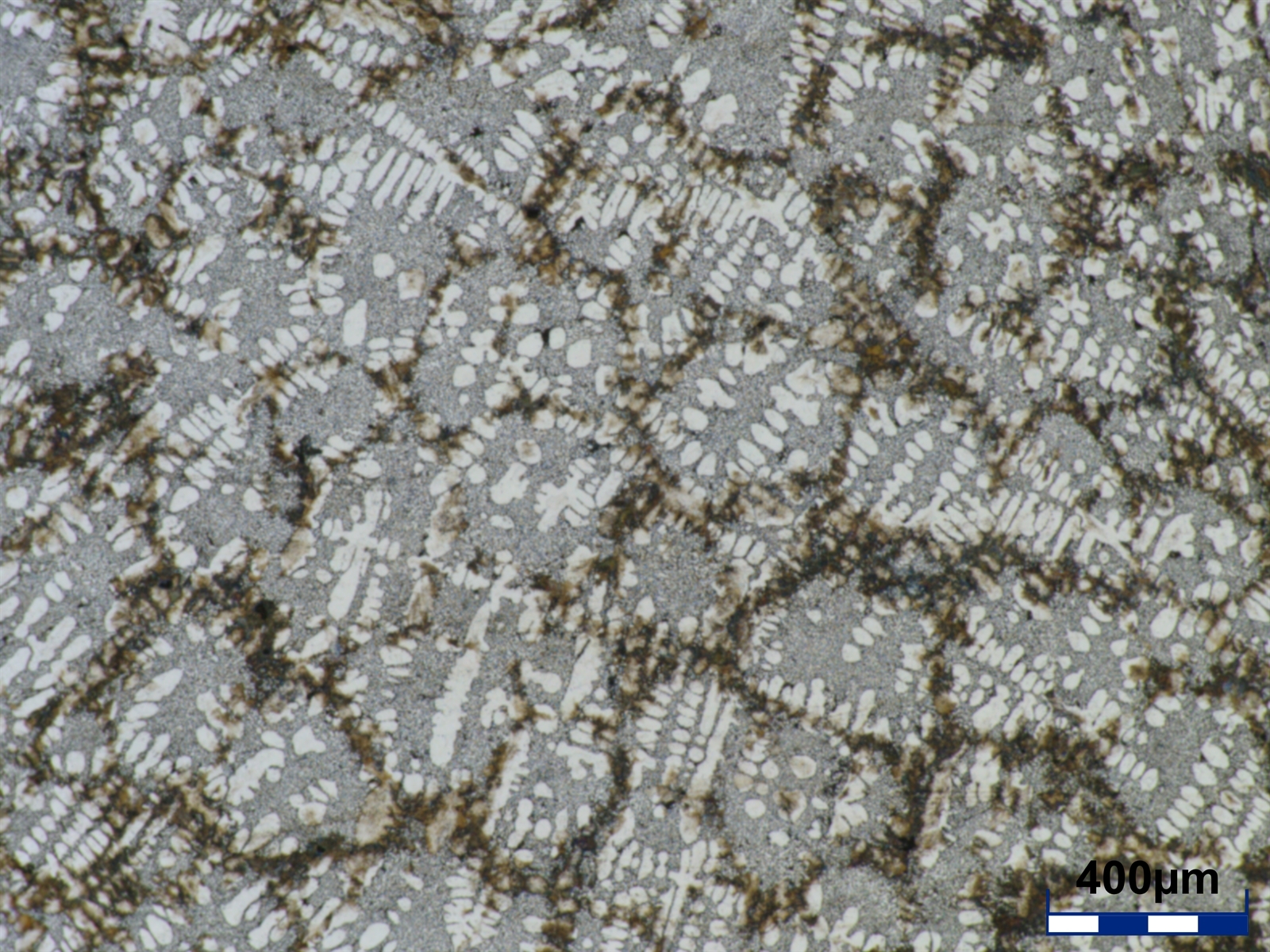

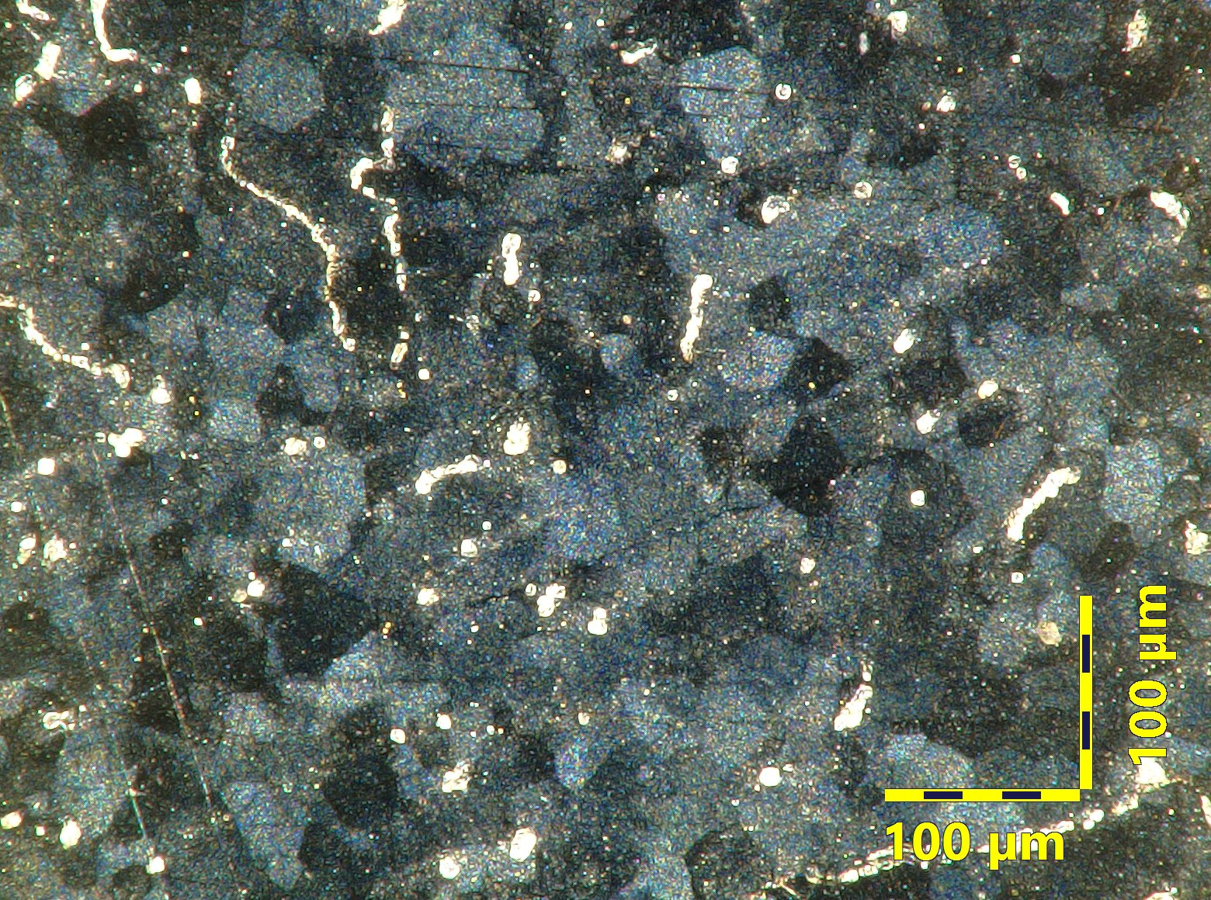

A special etching technique was developed to outline the fine grains in a a severely deformed aluminum sample.