Field Metallurgical Services

Positive Material Identification (PMI)

Our

technicians are

cross trained in instrument technology, alloy composition,

metallography, industrial standards and

statistical analysis. When we arrive on-site you can rest assured that

we are fully capable of providing your specific needs with accurate

results without damaging your parts. Put your trust in a certified

laboratory.

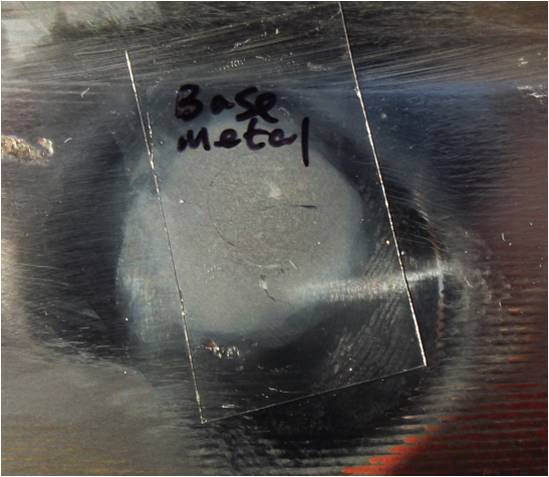

When exotic,

vintage or foreign material is spotted, the technicians get help from

the Ph.D in the lab. With many years' experience, based on the

appearance, chemical compositioin, in-situ macro and micro-structures

and hardness, we are able to identify nearly any metal or alloys, with

or without coatings. From wrought iron to Maraging alloys, from Armco

iron pipe to API X80, from electroless Ni coating to self-fluxed

thermal spray coating, from rimmed steel pipe to spun cast ET45 Micro,

from Chinese GB 20CrMnTi to French AFNOR 30NCD12, we have seen them all.

Heat Treatment Verification

-

We

are capable of differentiating between varying degrees of heat

treatment by using in-situ metallorgraphy and hardness testing. For

example, we can help grade out your Precipitation Hardened alloys

such as 17-4 PH, 15-7Mo PH and Inco 718. We can determine if your steel

was annealed, normalized, quenched/tempered or aged. All

these

can be done just by minor polishing.

Carbon Analysis/Content

-

As part of our PMI services we routinely measure Carbon in all alloys,

We measure carbon in L-Grade stainless in amounts as small as 0.008% by using OES and LIBS.

Nickel alloys pose no problem to us. Carbon steels are also easily measured and analyzed.

Custom Calibration

Our custom calibrations allow us to perform accurate assessments of your micro-alloyed materials. Examples would include A572-50, A500, API X65 and A709-50, When grading carbon steels accurate calibrations are critical.Hardness Testing

Hardness testing is sometimes regarded in a condenscending manner.-

However, when performed conscientiously, hardness testing provides

several valabule insights on a material’s properties.

-

Equipped

with UCI hardness testers with closest performance of the desktop

counterparts, our technicians are trained to perform this service in a

meticulously controlled fashion. This allows us to field-evaluate

material to a degree previously unattainable. We also have rebounder

type of hardness tester and Telebrinell.

Ferrite Content

We own 13 Fischer

Ferritescopes which

are the Cadillac of the field ferrite measuring industry.We are very

experienced in measurement and evaluation of duplex materials. We have

good experience regarding detection of the presence of sigma phase in

duplex/super duplex materials.Our documentation reports of these

examinations sets the industry standard and meets/exceeds all known

Specifications.We routinely measure the Ferrite content of austenitic

stainless steel welds.

Metallurgical Properties

We are capable of

filed-duplication of almost every lab procedure performed in the

petro-chemical and power generation industry.We have etched Inco 800 in

the field in out of position heater configurations.We have etched Super

Duplex material in a shop environment (within OSHA safety

regulations).We have performed Copper Sulfate tests in shop

environments and not violated OSHA regulations.

Elemental Composition

We typically render results in weighted averages.You will not receive a simple Identification Only(ID) reports from us.There are too many possibilities of error involved in simple ID evaluations based on analyzer/screen readouts.Our technicians do not simply “parrot” screen info…We analyze the weighted averages

We calculate/determine accuracy

We analyze the data

We report the results in a thorough, easy to understand report form

Ferroxyl Test for Free Iron

Ferro-Cyanide testing is not a problem for PMI Specialists.We can perform this test within all OSHA safety requirements.The results are stated in both data and verbiage reports.On Line (High Temp.) Alloy Verification

-

With 20 years experience in Retro PMI programs……we “wrote the book” on

this service.The ability of analyzers to perform this testing is the

result of our input to manufacturers.Our technicians have the field

savvy to inter-relate with the necessary support crews.We also are

capable of coordinating the overall operation.

Fitness For Service

Our ability to elicit pertinent information from various testing methods allows us to better evaluate your material. Our extensive array of instrumentation makes the tasks associated with Fitness For Service possible.Copper Sulfate Testing

We have provided this test for the presence of Iron in stainless steel for years.The spraying of the Copper Sulfate solution is performed within OSHA regulations. The results are reported on both database and metallurgical verbiage reports.Fire Damage Assessment

With in-stiu grain structure and hardness testing capabilities, we routinely perform fire damage assessment on steels and alloys for Oil rigs, Chemical plants and Refineries.