PMI SPECIALISTS, INC "WHEN YOU NEED TO KNOW"

Lab Equipment

Metallurgical Sample Preparation Equipments

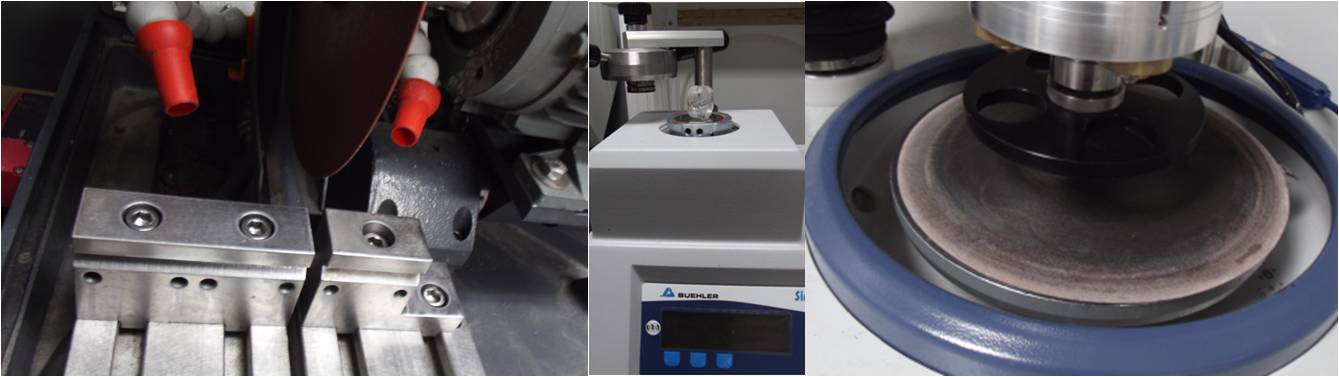

PMI specialists has full range of in-house sample prepareation equipments from cutting saws, cold and hot mounting, automatic polishers to electrochemical etchers.

Zeiss EVO MA-15 Variable Pressure Scanning Electron Microscope

Large Chamber: Sample diameter 10 inch x Height 6 inch. Resolution: 3 nm at 30kv HV mode, 5.5 VP mode.Magnification: 10x-100,000x.

Excellent low voltage imaging capability on sensitive materials.

Three detectors: SE, BSD and VP SE.

The VP SE detector enables imaging on polymer, ceramic, and corrosion products without sputter coating.

Through-Lens Pumping: Analysis of soil and wet samples.

Vapor Pressure:10 Pa – 400 Pa.

Dual Channel Viewing: SE and BSD images on both monitors.

Integral Chamber Scope: Easy sample viewing and switching.

IXRF SDD EDS with 126 ev resolution

SDD (Silicon Drift Detector) requires no liquid nitrogen for cooling.Capable of detecting elements above Be.

The increase in X-rays allows us to create very fast x-ray maps.

IXRF electronics are optimized to provide true “data streaming” for the fastest x-ray processing possible.

Digital Imaging, X-ray Elemental Mapping, and X-ray Spectra, are all computer controlled though the IXRF software and hardware.

Olympus DSX-1000 Ditigal Microscope

The new DSX1000 digital microscope combines the quality of renowned Olympus optics with the ease of use of digital technologies. It has 6 viewing modes (Bright Field, Dark Field, Oblique, Mixed, Polarization and Differential Interference Contrast. It can do 3D imaging and measurement automatically. With conventional microscopes, both a low-magnification and a high-magnification model are needed to complete an inspection. However, the DSX1000 digital microscope, with fully automatic moveable head and stage, is capable of 20-7000x magnification range on super large samples up to 2” (by stitching).Olympus Optical Microscope

The Olympus GX-51 inverted microscope is capable of doing bright field, dark filed and polarization imaging.The magnification ranges from 50x-1000x.

Pax-it Image Analysis Software

The Pax-it image analysis software is capable of doing:# Image Stitching

# Image Fusion

# Background Subtraction

# Image Blending

The software also comes with a scripting module, by which you can write your own code or standard for special analysis and perform batch processing of multiple images.

# ASTM Grain Size Analysis

# Plating Thickness

# Particle Count and Distribution

# Porosity

# Nodularity

# Ferrite/Pearlite

# ASTM Flask Size Classification

The imaging software is equipped with a scripting module.

This allows us to write our own code standard for special analysis.

We can also perform batch processing of multiple images.

Stereoscopes

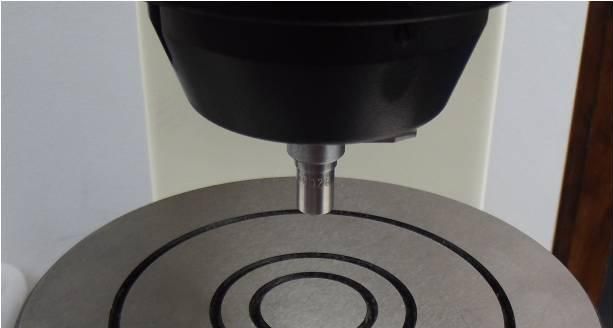

Magnification ranges from 7x-180x.Phase II Rockwell Hardness Tester

Capable of doing Rockwell A, B, C, F and G sacle with loading from 60, 100 and 150 kgf.Digital Microhardness Tester

The automatic digital microhardness is equipped with two indenters (vickers and knoop) with loading ranging from 10 g to 2 kg.Field Equipments

PMI specialists has the most modern industry leading equipment necessary to perform accurate determination of elemental composition of customer samples and the subsequent reporting of the results.

X-ray Fluorescence (XRF) Analyzers

We own 20 XRF analyzers with SDD detector.X-ray Fluorescence (XRF) is a non-destructive technique that is used to quantify the elemental composition in samples. X-rays excite atoms in materials, causing them to emit x-rays with energies characteristic of each element present. The intensity and energy of these x-rays are then measured. Through the use of appropriate reference standards, XRF can accurately quantify the elemental composition of both solid and liquid samples.

Optical Emission Spectrometer (OES) Analyzers

We own 14 OES analyzers.Optical Emission Spectroscopy excites atoms in a sample.

This is accomplished by a spark formed between sample and electrode. The energy of the spark causes the electrons in the sample to emit light. This is converted into a measurable spectral pattern.

The peaks in this spectrum produce qualitative and quantitative analysis of a huge amount of elements including carbon. OES accurately measures Carbon in alloys down to 0.02 wt% level.

Laser Induced Breakdown Spectroscopy (LIBS) Analyzers

Laser-induced breakdown spectroscopy (LIBS) is similar as spark OES. It fires a pulsed laser at the metal to create a plasma, instead of a continuous electric spark-like spark OES. Light from the plasma is measured with an onboard spectrometer to determine individual wavelengths and thus what elements are present. The elemental content is quantified via onboard calibrations.We have multiple units of Sciaps Z series, the world’s only handheld analyzer that delivers carbon content in steels, cast irons and even L-grades stainless steels.

Fischer Ferritescopes

Non-destructive measurement of ferrite content in a range of 0.1 to 80% Fe in Austenitic & Duplex Stainless Steels and weldments..Microscopy Kits

Microphotographs at 40-1000x are produced on finished parts to identify grainstructure and mechanical properties.GE MIC10 Hardness Tester

The GE MIC 10 enables quick and convenient on-site hardness testing according to the UCI method (Ultrasonic Contact Impedance standardized according to ASTM A1038). The diamond indent in the material’s surface is electronically measured and instantly displayed without using the cumbersome optical evaluation normally associated with conventional hardness testers.Proceq Equotip 3 Leeb Rebounder Hardness Tester

Based on ASTM A956, It measures the Leeb value (L) for materials, which is a ratio of the impact velocity to the rebound velocity. It has a large measuring range - from soft to extremely hard. It is most suitable for thick samples and cast irons.Telebrinell Portable Hardness Tester

The Telebrineller system is based on ASTM A833. It is a simple to use tool based on proven metallurgical knowledge supported by more than fifty years of field experience. By a hammer blow, measurement of the resulting impressions, and the manipulation of a basic equation on the computer provided, very accurate hardness readings can be obtained.