PMI SPECIALISTS, INC "WHEN YOU NEED TO KNOW"

Failure Analysis

Products

do fail. When

it happens, the results could be very

costly. Failure analysis and prevention are important functions to all

of the engineering disciplines. At PMI specialists, we specialize in

failure analysis in metal alloys, polymers and ceramics. We will find

out if a failure is caused by inappropriate material selection, design,

and fabrication or operating conditions. In any case, PMI specialists

will help determine the cause of failure to prevent future occurrence,

and to improve the performance of the device, component or structure.

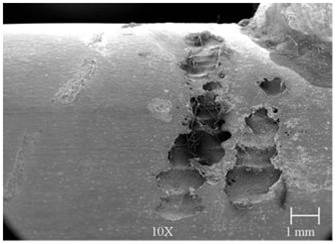

Having state of the art Scanning Electron Microscope (SEM) with SDD Energy Dispersive x-Spectrometry (EDS) detector, latest software and extensive sample preparation methods, PMI specialists is well equipped for failure and corrosion investigation.

Some of the components for failure analysis that we look at usually include mechanical equipments; heat exchangers, heater & boiler tubes; pipelines; pumps, pressure vessels; forgings; castings; welds/brazes; tools and dies.

Every case of failure is different. However, there is a good chance that similar failure had occurred before and reported. PMI specialists have the access to tens of thousands of research articles on failure analysis and prevention. In addition to our experienced PhD-level materials engineer, the failure analysis at PMI specialists is also backed by chemists, finite element analysts and mechanical engineer consultants.

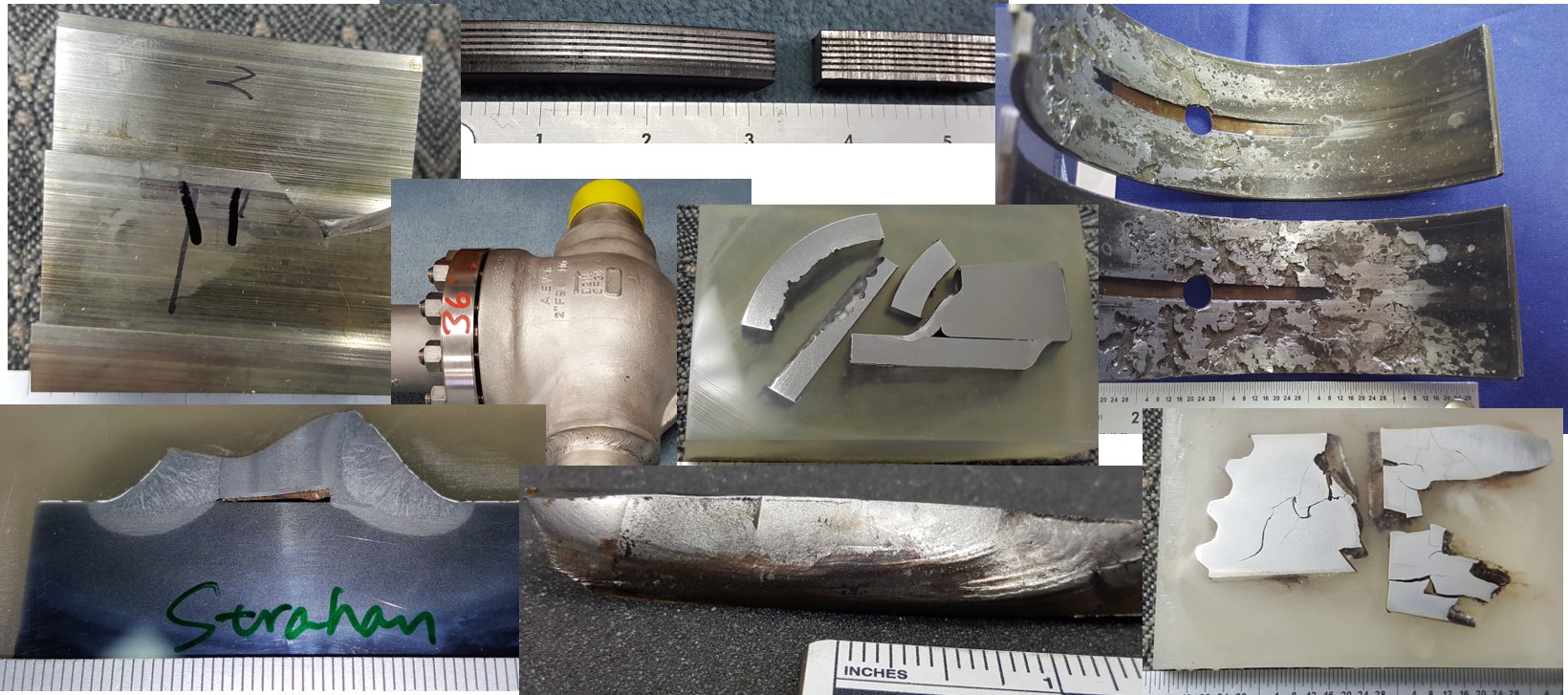

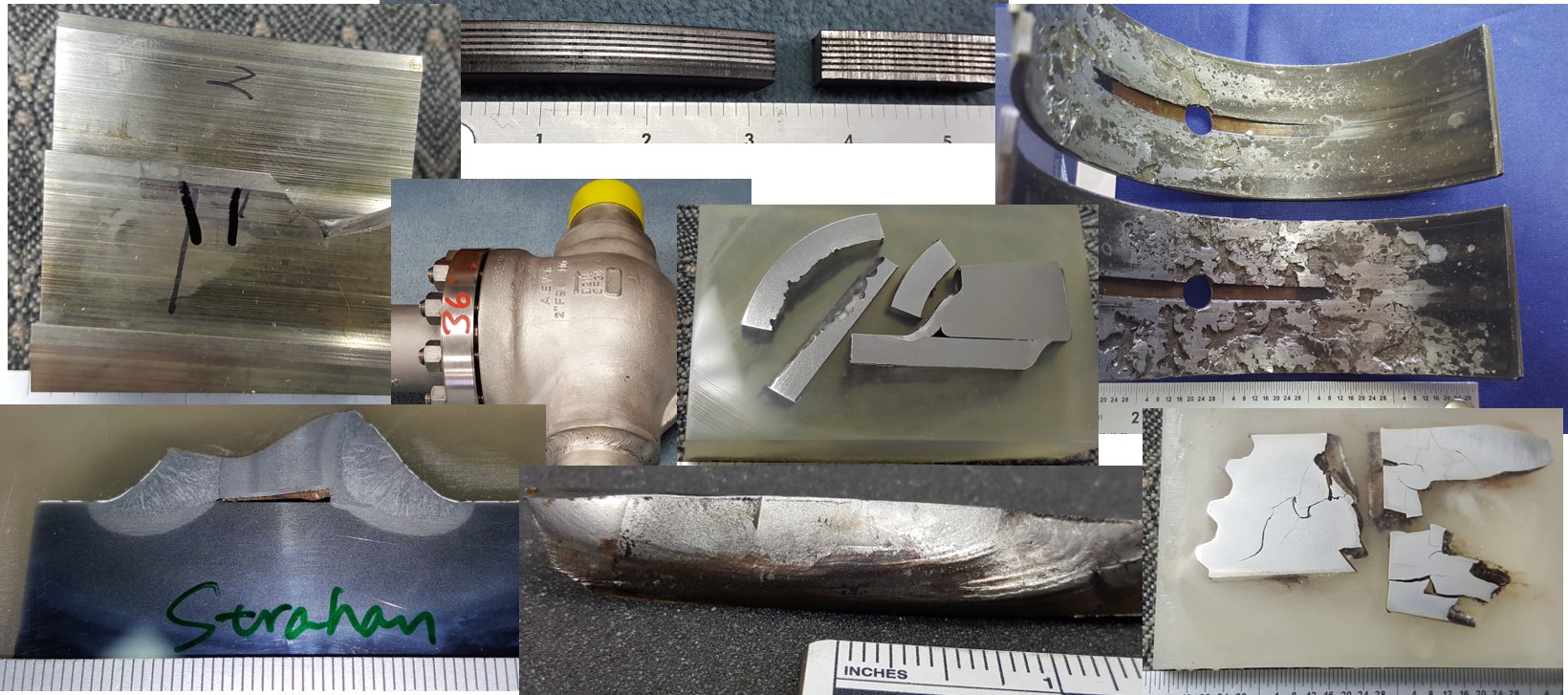

The following pictures are just some examples we have done recently. While the majority of analysis are on common metal and alloys, we have performed a good amount of studies on Cast iron, Telfon gasket, Galss liner, Nickel based braze, Silicon nitride thermowell sheath, Zirconia mud pump Liner, Oxide dispersed high temp alloys, Babbit bearing and Rear earth element modified Mg alloys, just to name a few.

Having state of the art Scanning Electron Microscope (SEM) with SDD Energy Dispersive x-Spectrometry (EDS) detector, latest software and extensive sample preparation methods, PMI specialists is well equipped for failure and corrosion investigation.

Some of the components for failure analysis that we look at usually include mechanical equipments; heat exchangers, heater & boiler tubes; pipelines; pumps, pressure vessels; forgings; castings; welds/brazes; tools and dies.

Every case of failure is different. However, there is a good chance that similar failure had occurred before and reported. PMI specialists have the access to tens of thousands of research articles on failure analysis and prevention. In addition to our experienced PhD-level materials engineer, the failure analysis at PMI specialists is also backed by chemists, finite element analysts and mechanical engineer consultants.

The following pictures are just some examples we have done recently. While the majority of analysis are on common metal and alloys, we have performed a good amount of studies on Cast iron, Telfon gasket, Galss liner, Nickel based braze, Silicon nitride thermowell sheath, Zirconia mud pump Liner, Oxide dispersed high temp alloys, Babbit bearing and Rear earth element modified Mg alloys, just to name a few.